Welding involves the process of joining two different pieces of metal. Welding is evident in many forms around us; like a car, the gates, many household items, the list is endless. From indoors to outdoors, underwater to spaces; welding is performed in all kinds of environment. There are various types of welding operations, but the TIG welding also known as the Tungsten Inert Gas Welding is the most advanced type and requires skillful welders to perform it. So let’s get started with the TIG Welding basics in this article.

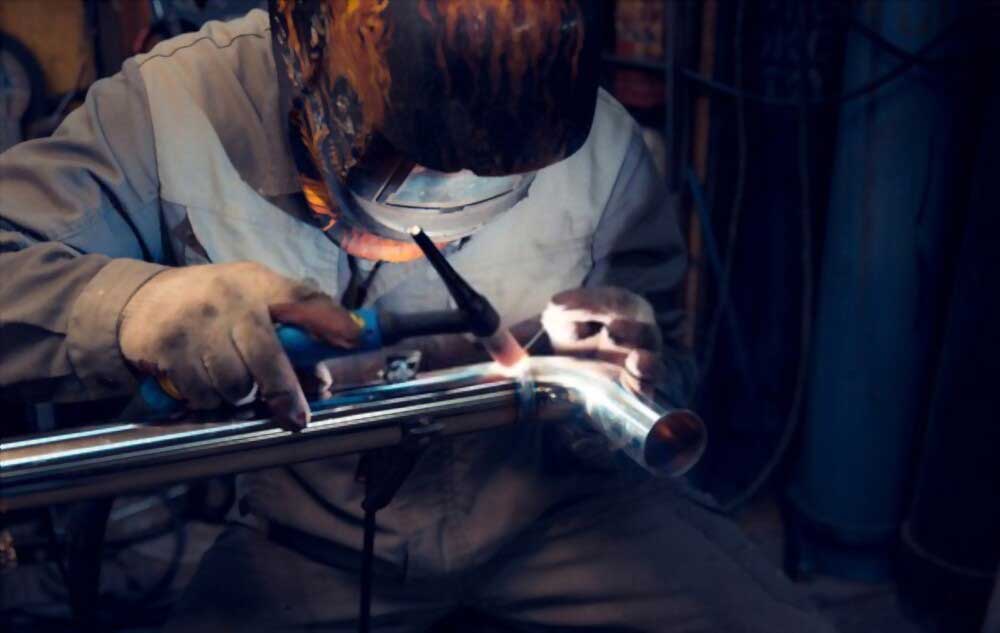

What makes the TIG welding different from other types of welding is the arc which is created and the way the filler material is added while welding. These two factors form the basis of how TIG Welding works. It is the most difficult among all the welding types. It is a manual process wherein the welders hold the TIG Torch with one hand to create the arc and fill in the filler material using the other hand. This is how TIG welding works. Although a difficult method, it is the most versatile one and produces the highest quality welds if conducted with some powerful units.

Tig Welding Basics

The Tungsten Inert Gas welding is also known by the name of GTAW, Gas Tungsten Arc Welding. The process involves creating an electric arc by the use of tungsten electrodes. The power supply generates heat, which produces an electric arc between the metal workpiece and the tungsten electrode. The heat generated welds the two metal pieces. This process is performed in the presence of inert gas like Argon a Helium to prevent atmospheric contamination.

1. How a Tig Welder Works

This section deals with the TIG welding basics for engineers. The main components involved in the TIG welding heat, shielding by inert gas and the filling material. Let’s get to know how does a TIG welder works:

1. The metal workpiece on which the welding is to be performed is decontaminated by passing the inert gas or shielding gas, namely, Argon or Helium.

2. The torch is held over the metal such that it is just near the surface but does not actually touch it.

3. Upon pressing the foot pedal by the welder, the tungsten electrode produces an arc. On the generation of an arc, the two metals melt and create a puddle in which the welder carefully inserts the filler material by manually dipping the welding wire.

This is the technique involved in joining two metal Pieces by TIG welding.

2. What It Takes to Start Tig Welding

TIG welding involves a lot of precision as it is done manually. The right set of equipment needed to set up your TIG welders are:

TIG Torches: They are either water-cooled or air-cooled. The incorporation of either type of TIG torch depends upon the welder. The TIG torches with all the control settings on the torch handle give a better edge to the welder since the other hand is involved in filling the filler material.

Type of Electrode

The high-quality electrodes will not only produce a strong weld but will also provide a stable arc for welding. Choosing the electrode depends upon the type of metals being welded and the welding joint.

The tungsten electrodes are considered non-consumable, but they definitely burn off over a period of time. So lesser the burn-off, the better the electrode and the weld being produced.

There is thoriated lanthanated and ceriated type of electrodes. The thoriated ones are long lasting but they emanate radioactive dust which is harmful. Lanthanated electrodes have the same benefits as thoriated and also do not produce radioactive dust. The ceriated electrodes are the preferred ones as they function well even at low amperes and give an easy arc start.

Grinding Wheels

The grinding wheels are an important accessory to be considered in a TIG welding set up. The electrode needs to be ground either into a tip or a ball depending upon the welding project and the metals. Make sure the grinding wheels are free of contaminants as it can damage the electrodes.

Shielding Gas

The shielding gas can be used either individually or as a mix. The heat transfer that the gas permits become the deciding factor for welding thicker or thinner materials. Helium is preferred for thicker materials over pure Argon; whereas for thin materials a mix of Helium and Argon is used.

3. Uses of A TIG Welder

TIG is used in many industrial applications which require high-quality welds. The following are the areas where the TIG welding is made use of:

- In the manufacturing of chemical plants for boilers

- In the materials where a relatively small Arc is needed to be produced

- It is also used in mechanized systems other autogenously or manually.

There are various applications of TIG welding the TIG welders are used for:

- Welding thin sections of stainless steel and non-ferrous metals like magnesium, aluminum and copper alloys.

- In the aerospace industry, metals like aluminum are used which are light. TIG welding is more suitable here as it produces high-quality welding compared to MIG, Metal Inert Gas welding.

- In Bicycle industry where small diameter and thin wall tubing are needed the TIG weldings are used.

- In other industrial purposes like piping and joining thin materials in the automobile industry.

4. Safety Considerations

TIG welding work involves various hazardous fumes and elements. The proper knowledge of TIG welding tips and safety measures will ensure and reduce any kind of risk associated with the process. If proper precautions are taken, the hazards related to welding can be reduced. The TIG welding involves emission of dust, smoke which can cause occupational diseases in the long run. The high temperature, electric shock, and harmful radiations can cause accidents. So here are a few TIG welding tips to ensure safety while welding:

- Stable and smooth work area to provide a steady ground for work

- The clothes worn by the welders should be of non-flammable material to avoid catching fire. Welding apron or jackets made up of leather is a good option.

- Safety gears in TIG welding include welding helmets and welding gloves, long sleeve shirts and pants, heavy work boots. These are the prerequisite for any welder before welding to avoid self-injury.

- The area where welding is being performed should be dry and no trace of water should be present as water is a good conductor of electricity.

- The shielding gas and oxygen cylinders should be stored in a safe place and an upright position. They should be away from sparks to prevent any kind of explosion.

- When you work with the TIG welder make sure the workspace is well ventilated as the TIG welding emits fumes of the smoke switch are very harmful.

5. Prospects of Tig Welding

There are various career opportunities for people trained in TIG welding. It is a unique, specialized technique which requires a skilled person to perform the welding. For TIG welders, here are a few career opportunities:

1. Structural Welding: A structural welder should be well versed with the welding of metals and nonmetals

2. Pipe Welding: Pipe welders can land themselves a job at the construction site where installation of the pipe is being done. They must have a good knowledge of welding various metals and alloys.

3. Aircraft Welding: The aircraft welders are highly paid as they will part used in the construction of aircraft, they are also responsible for repair and maintenance of the welded parts. They should possess sharp skills and follow safety measures for passenger safety.

TIG welding is immensely important and a sought-after in industrial welding, just like MIG welding. It does require time, practice, and good knowledge but the welding produced is of high quality. The proper knowledge of how does the TIG welding work coupled with experience will land good career opportunities for the TIG welders.