Want a woodworking tool that checks the uneven edges, flatness, and surfaces? A jointer proves to be useful. What if you need to deal with the wood twists on several spots on a large stock? Again, a machine that is more powerful than an average jointer seems to be a nice thing to own.

But how can you make sure that the right one is in your collection? I’ve years of experience working with them, and this article is what the Drillly team has managed to present you to help you decide how much power, what construction, how much to spend, and much more to get the perfect benchtop jointer for you.

However, it’s always a good thing to be sure of why you should even get a benchtop machine. So, I’m about to inform you of the many uses a jointer offers, and then, I’ll talk about the other factors plus some of the most popular choices.

11 Best Benchtop Jointers Tested and Reviewed

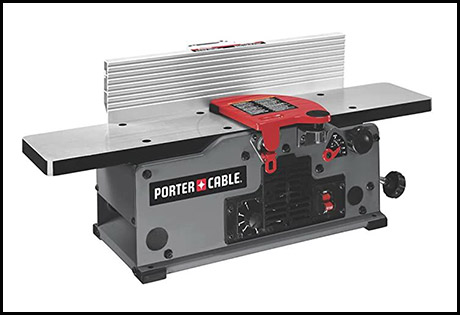

01 PORTER CABLE PC160JT (Top Pick)

Portable Cable has a reputation for its outstanding power tools which has helped woodworkers on low-budget to have a glimpse of one of the top-rated jointer models. The PC160JT features a variable speed 6000 to 11,000RPM which allows you to choose the needed speed for the size and material of the wood being cut.

You can change or adjust the HSS knives easily while maneuvering the flexible fence. This is very useful for beginners who would love to go easy with the fence. You’ll appreciate the cutterhead lock designed to keep you safe while you’re making the changes.

One of the greatest assets of the PC160JT is its 30-inch size table that allows you to work with some thick boards while still enjoying the comfort. However, the fence is made of aluminum and needs to be re-squared each time you use it which is one of the things you can expect from a budget power tool like this.

What we liked about this product are the positive stops which help to simplify the operation by letting you adjust the fence between 45 and 90 degrees. Also, the workpiece is fully stable during the cut to offer you a smooth and accurate edge.

Another feature worth mentioning is the 4-inch dust port that allows it to suck off dust particles from the machine while keeping your work environment clean and safe. In addition, the 3-year warranty form Porter Cable does not only help you to feel secure with the product but clears away doubts as to the reason it should appear on this list.

Specifications

- Weight: 35 pounds

- Dimensions: 32.1 x 12.4 x 11.2 inches

- Maximum cutting width: 6-inches

- Cut depth: 1/8 inches

- Motor Power: 1.4HP

- Variable Speed: 6000-11000RPM

- Cuts per minute: 12000-22000

- Table size: 30 inches

Pros

- It is portable and lightweight

- The variable speed allows you to cut woods of several sizes and materials

- The knife blades can be replaced easily

- It comes with a 3-year warranty

- Its spare parts are readily available for replacements

Cons

- Many users are uncomfortable with the aluminum fence

- The table top may not last long

Our Verdict

The PC160JT is a great tool for sale with a weight of 35 pounds that allows it to be stored or transported easily. In addition, it has a variable speed of 6000 to 11000RPM to allow you to set the needed speed for the size and material of the wood.

One of the greatest advantages of this model is that it features a large table that accepts small and bigger woods alike. This is an affordable choice designed to meet the needs of both amateur and professional users.

02 Delta 37-071 (Also Great)

If you have a budget in mind but interested in employing something for perfectly smoothed and flattened wood edges, this product delivers.

The Delta 37-071 comes with a stable and sturdy build. The fence and the table are thoughtfully designed to make your operation safe and comfortable. The simplicity of its use is commendable. While it may take some time to align the fence, it stays fixed once you get over with.

What we also liked about this model is the ease of changing the blades. In addition, it is built from cast iron to enhance its durability unlike many of the benchtop jointers for sale which are constructed from aluminum. Another important thing is that this sturdy construction helps withstand the vibrations that may mar your workpiece when you are doing the cutting.

One of the first things that struck us about this machine was its 1.5HP motor power that rotated the cutterhead at a speed of 10,000RPM. You may not be very impressed with the weight of 76 pounds; however, the advantage is that it allows the machine to stay stable during operation.

Still, on the design, it’s made to handle a 6-inch timber with ease. It can also penetrate woods to a depth of 1/8 inch at a maximum cut rate of 20,000 CPM. You will be shocked that it comes with straight blades to ensure you have an even and precise cutting.

Its fence can be easily adjusted to support your workpiece and can be tilted at an angle range from 45 to 90 degrees, whereas the Shopmaster JT160 has a center-mounted fence. There’s a built-in dust collection system that helps to keep your workshop safe and free of dust. However, you will still need a workshop vacuum to clear any extra debris from your sight.

Specifications

- Weight: 76 pounds

- Dimensions: 35 x 17 x 13 inches

- width of cut: 6 inches

- cut depth: 1/8 inch

- Cuts per minute: 20000CPM

- Number of knives: 2

- Aluminum cutterhead diameter: 1 7/8 inch

- Table dimensions: 6 ¼ x 28 ½ inches

- Fence dimensions: 4 5/16 x 22 7/8 inches

- Chip chute opening: 2 ¼ x 2 3/8 inches

- Base dimensions: 11 ½ x 21 inches

Pros

- It is constructed from cast iron to make it sturdy and durable

- The 1.5HP motor represents an excellent value for the money

- The integrated dust collector helps to keep the shop safe

- It comes with 5-year warranty

- The table and fence can be adjusted with ease

- It can be used with hardwood

Cons

- It has only two blades for cutting

- Everything is operated manually

Our Verdict

Delta 37-071 is designed to handle your small wood pieces. It is affordable yet packed with features to help you to enjoy a smooth and accurate operation. But the most significant is its cast-iron body that keeps it stable during the cutting process.

However, its straight knives may not reduce its performance when compared with models that feature the spiral cutterheads. The Delta Power Tool really has amazing features at an affordable price point.

03 Grizzly G0725 (The Most Durable Option)

If your expectation is to buy a heavy-duty jointer that is durable and sturdy, the Grizzly G0725 is the option for you. The table, fence and the entire body of this jointer is made from cast iron. Also, the adjustment knobs and other parts of this machine are made from steel. It was shocking when we discovered that the power switch is the only part of this device that is made from plastic; however, the other specifications of the machine are strong enough to suit your demands.

The Grizzly G0725 weighs 81.2 pounds, although it’s a little heavy, so it will require a dedicated space for storage. Also, the table is a little larger than most of its competitors which means you will have a comfortable space to handle longer and bigger woods. However, we noticed that it is a little difficult to adjust the infeed board with its adjustment gear located under the table.

You may not appreciate the lack of flexibility in the adjustment of the table, but you will like the ease with which you can adjust the fence stops between 45 to 135 degrees.

The cutterhead is the same as most of the best-rated models we have here. With its two-blade design and the ability to run at a speed of 10,000RPM, this machine will produce an accurate, fast, and smooth cutting operation. It can penetrate the wood piece to a maximum depth of 1/8 inches which is the ideal depth for any benchtop jointer.

The Grizzly G0725 features a dust collection system through a dust port of 2 – 1 ½ inch, just like the G0821 or the G0604X from the same brand. This cleaning mechanism helps to keep the workshop free from dust while enhancing the lifespan of the machine.

Specifications

- Weight: 81.2 pounds

- Dimensions: 15 x 32.5 x 11.2 inches

- Cutterhead speed:10000RPM

- Cuts per minute: 20000CPM

- cut depth: 1/8 inches

- Table size: 28 1/2 x 6 ¼ inches

- Fence size: 22 7/8 x 4 5/8 inches

- Dust port: 2 ½ inches

- Warranty: 1 year

Pros

- It is constructed from durable materials like cast iron and steel

- The infeed table is slightly long

- It comes with a dust collection system

- It has a flexible fence

Cons

- The infeed table height is very difficult to adjust

- The cutterhead has two blades only

Our Verdict

Coming in under 1000 USD, the Grizzly G0725 will serve you for years. It is affordable with a solid body which makes it suitable for large sized wooden boards. Its 1-1/2-inch dust port not only helps prolong the life of the machine but helps keep the workshop environment clean and free from dust particles. Its portability cannot be ruled off totally and it’s a great choice for workshops with limited space.

04 Jet JJP-8BT

We put the JJP-8BT on our top 10 list for a number of reasons. During testing, we found that this compact little benchtop planer and jointer combo worked remarkably well yet taking a tiny space in one of our workshops.

First of all, this 67-lb power tool is 32.5 inches long and 17.2 inches wide with 5.8 inches high. It’s small size will barely remind you that it houses a 3 HP motor that generates 18 thousand cuts a minute. The sheer number of the cut effortlessly ensures polished smoothness on your working board.

Secondly, it’s got multiple height adjustment features for you to properly align your piece at different thickness points. Once our team got familiar with the tool, the adjustment time shortened.

Thirdly, you can angle the housed aluminum fence by up to forty-five degrees this way the joints will be more stable. We also found a pointer and a scale that read the gap between the cutter head and the resting table. The oversized knobs are ergonomically designed for providing comfort during working.

Finally, you’ll get a cord wrap integrated to the machine for simple mobility and ensuring safety from dangling electric wires and plugs. And apart from safety, you are doing two facilities of jointing and planing in one machine.

Specifications

- Height– 15.8 Inches

- Width–17.2 Inches

- Length– 32.5 Inches

- Cutting rate– 18k Cut Per Minute

- Feed Speed– 19.5 Feed Per Minute

- Highest Cutting Width– 8 In.

- Jointer Top Cutting Depth– 0.125 Inch

- Highest Cutting Depth (Planer)– 0.08 Inch

- Highest Cutting Capacity (Planer): W-0.20 Inch x D-4.72 In.

- Cutterhead Speed—9 thousand RPM

- Knives: 2

- Knife Size (Standard)– 8-0.25 x 0.65 x 0.06 (In.)

- Motor Voltage (Volt)– 115

- Prewire Voltage (Volts)– 115

- Motor Current–13 Amp.

Pros

- Compact and small

- Versatile combo with two tools

- Ergonomic adjustment knobs

- Lightweight and easily portable

- Robust motor

- Metal out-feed table

- Easy adjusting features

Cons

- Poor dust collection option

- Cleaning required before startup

Our Verdict

The Jet JJP-8BT is a fabulous combo power tool from the JET production line. We found it highly efficient in planing and joining boards. One of the biggest merits of the tool is its size. You can place it in a tiny workshop and run heavy-duty projects with no problem. Get this on your shopping cart if you need a compact yet powerful machine with all the standard features.

05 Shop Fox W1829

The W1829 is among the most popular benchtop jointer models from Shop Fox’s production line. It is designed for woodworkers with tight budgets and those interested in a product that offers an acceptable level of precision.

What we liked about this product is that its overall body is made from cast iron and that includes its fence as well as infeed and outfeed tables to make it stable while shaping hardwoods. It weighs 80 pounds, the number that would dissuade many users from falling for its portability, but it can still be transported to and from the work site without difficulties.

One of the things you will notice about this model is that it features a 12A powerful motor with a power and speed rating of 1.5HP and 10,000RPM. This implies that it can cut through some heavy-duty wooden boards with ease without compromising with the accuracy and shape of the edges.

Another feature we liked is the flexibility of the fence which allows it to be adjusted to angles of 45, 90, and 135 degrees respectively. The best part about Shop Fox W1829 is how easily you are able to use this bench jointer. It comes with a cutting depth of 1/8 inch which can be easily adjusted to suit the type and size of the wood piece.

You will appreciate its unparalleled dust collection system which features a 2 -1/2 port and a bag. This mechanism helps to keep your workspace away from dust while making it easy for you to maintain the machine.

Finally, the Shop Fox W1829 comes with a 2-year warranty that does not only cover any defect that may come with the machine but is a guarantee that you can operate the machine with confidence.

Specifications

- Weight: 80 pounds

- Dimensions: 29.5 x 19.8 x 12.5 inches

- Power: 1.5HP

- Cutter speed: 10,000RPM

- Cuts per minute: 20,000CPM

- Dust port: 2-1/2 inches

- Warranty: 2 years

Pros

- The cutterhead and fence can be adjusted easily

- The table is made from cast iron which enhances its stability

- It comes with a dust collection feature

- It is very cheap

Cons

- The table and fence may not be stable

- The cutterhead has two blades only

- The fence is made from aluminum material

Our Verdict

Shop Fox W1829 combines affordability and durability to offer you a product with features that can handle many of your wood pieces with ease and accuracy. It features an adjustable fence to let you fine tune the cuttings to suit the size and type of wood you’re cutting.

However, many users may not appreciate the aluminum fence, but you can expect from a cheaper option like this one. Moreover, this defect is covered by its 2-year warranty.

06 RIKON 20-600H

If you want to buy a portable benchtop jointer that will offer you a smooth and flat edge surface based on your desire, the RIKON 20-600H is what you need. Also, if you have a limited amount of money but you want a product that is dependable and durable, this is what you are looking for.

It weighs 36 pounds, making it a fine compact and portable choice. You can transport it easily to anywhere and with dimensions of 30 x 17.5 x 13 inches, it will take just a little space in your workshop while giving more room for other equipment and air.

This unit is no different from other shortlisted products here in terms of its cut depth, which is 1/8 inch. Also, it comes with a motor speed of 11,000RPM to spin its helical cutterhead and the HSS inserts.

The inserts can cut using either of its two edges which does not only help in terms of smoothness and speed of the cut but prolongs the life of the blades. Once you notice that any of the sides of the blades is worn, all you need to do is to get it sharpened, and when the two sides must have been worn completely, then you can replace them.

Another thing we liked about this machine is its 30-inch table which allows you to perform tasks on slightly longer wooden boards than you would with most of its competitor jointers. In addition, the fence can be adjusted from 90 to 135 degrees and with dimensions of 19 ¾ x 4 3/8 inches, you are sure to obtain reasonable support for your workpiece.

You will also notice its superb depth setting with an easy to read scale which lets you determine the thickness of the cut with ease. In addition, you will appreciate its dust collection port to allow you to hook the machine to a vacuum cleaner. This helps clear the accumulated dust from the machine while your work environment is kept safe and clean.

Moreover, the RIKON 20-600H features an easy to reach on/off switch at its front panel to help you to power off the machine during an emergency. If you always look for warranties, the 5-year warranty will surely surprise you.

Specifications

- Weight: 36 pounds

- Dimensions: 30 x 17.5 x 13 inches

- Voltage: 120V

- Wattage: 1200watts

- Cutting width: 6 inches

- Cut depth: 1/8 inch

- Table: 30 inches

- Speed: 11000RPM

- Dust port: 2- ½ inch

- Warranty: 5 years

Pros

- Great for users with space issues and

- Easy to carry

- It has all-steel construction

- It is lightweight yet durable

- The blades can be accessed easily

- The table can accommodate thicker wooden boards

- The depth setting is marked for your convenience

Cons

- It comes with two blades only

- Dust tends to build too quickly on the machine

Our Verdict

The RIKON 20-600H is very affordable and dependable. It features an 11,000 RPM motor that can cut through slightly thick wooden boards with ease and precision. The two-edged blades help you to save the cost of replacement by using only one side at a time for cutting. Once the two sides are completely worn out, you can either sharpen them or get a replacement.

This unit is recommended for beginners who intend to improve their wood smoothening and planing skills with a budget-friendly jointer.

07 Jet JJP-10BTOS

The Jet JJP-10BTOS is a great jointer planer combo, which means it vanishes the differences between a jointer and a planer, offering you the best of both worlds. It comes with numerous specs which are common with most of the free-standing jointers for sale. Now let’s discuss its major features.

It is relatively portable and lightweight without compromising its efficiency. It is a combination of the jointer and the planer that not only does maximize your limited storage space but saves you the cost of buying separate equipment. So, you get the power of both worlds.

You will notice that the tables for planing and jointing are locked to offer you an accurate cutting. Moreover, the Jet JJP-10BTOS features a cutting speed of 18,000CPM and a maximum cut width of 10 -inches to help you to handle both large and small pieces of wood with ease. Also, the jointer’s cut depth is 1/8 inches while the maximum cut depth of the planer is 0.8 inch.

In addition, this unit features a steel stand to help you configure the machine from a benchtop to a standing type comfortably. The Jet JJP-10BTOS is equipped with an outfeed table that can be adjusted to accommodate a longer size of wood. The fence can be adjusted up to 45 degrees to obtain the needed stability for effective and smooth cutting.

Another feature that is worth mentioning is the scale and pointer on the planer that helps you to determine the accurate distance between the cutter head and the table.

Finally, the Jet JJP-10BTOS allows you to have a safe and comfortable operation by featuring two easily accessible knobs. You will notice that the control knob is large and user-friendly to help you to access it conveniently.

Specifications

- Weight: 84 pounds

- Dimensions: 40.4 x 20 x 17 inches

- Style: jointer/planer

- Voltage: 116V

- Size: 36 inches

- Color: Port

- Cutting width: 10 inches

- Cutting depth: 1/8 inches

- Fence: 4 7/8 x 25

- Speed: 9000RPM

- Cut per minute: 18000

- Warranty: 3 years

Pros

- It comes with a jointer and planer combo

- The controls are user-friendly

- The fence can be adjusted

- It has a larger cutting width

- It can be configured from a benchtop to a free-standing type

Cons

- The fence is made from aluminum

- The maximum angle for fence adjustment is 45 degrees

Our Verdict

The Jet JJP-10BTOS is one of the products from the JET production line with an excellent performance. It is equipped to perform as a jointer and a planer in a single unit. The planer is equipped with a scale to assist you while adjusting the distance between the cutterhead and the table.

This machine is designed with user-friendly features to help you enjoy its usage. In addition to its portability and compact build, it comes with a 3-year warranty to boost your confidence its durability and reliability.

08 CRAFTSMAN CMEW020 10 Amp Benchtop Jointer

The CMEW020 by Craftsman is a killer when you consider its features and excellent service. With the variable speed (6000-11000 RPM) powerful 10 amp motor this machine can perform 12 thousand to 22 thousand CPT (cuts per minute). No matter what kind of material you use, you can always set the right cutting speed to achieve optimum precision.

The cutter head, on the other hand, is designed with two knives. We were able to level the knives using the existing jackscrew. We also found a head lock for the cutter that was a built-in feature, turned out to be really handy when replacing or adjusting the knives.

The 39.8 lbs. power tool has a center-mounted fence that provides enough support for achieving precision cutting for any type of wood.

Sadly, we didn’t get a dust collection bag coming with the package. We had to buy that separately. The overall design of the product is superbly futuristic. We liked the red color which has a psychologically uplifting effect on the workers.

If you care about your safety just like you care about the smoothness of your wood, then this product works perfectly for you. It is designed with a safety power switch Lock to help you to kill the machine’s power easily and comfortably during an emergency.

Specifications

- Weight: 39.8 lbs.

- Dimensions: 32” x 12.4” x 11.2”

- Motor: 10 amp

- Voltage: 120V

- Cutter head: two-knife

- Table: 30 inches

- Speed: 11000RPM

- Warranty: Full lifetime

Pros

- Durable build

- Fantastic look

- Powerful 10 amp motor

- Variable speed for different materials

- Cutter head has two-knife design

- Lifetime warranty

Cons

- Heavy, not a good portable option

- No dust collector comes with the package

Our Verdict

The Craftsman CMEW020 is very affordable and dependable. It features an 11,000 RPM motor that can cut through slightly thick wooden boards with ease and precision. There are enough options for knife adjustments and replacement. Get the machine if you want smooth cuts and consistent performance.

09 Grizzly Industrial G0893-6″ Benchtop Jointer with Spiral Cutterhead

As you all know, nothing beats the silky smoothness generated by a spiral cutterhead. Grizzly Industrial added this amazing feature in their G series benchtop jointer. Just like its former models G0893 packs all the goodness of spiral cutters where each of 18 carbide inserts in each of four cutting surfaces is independently adjustable, just rotate the insert before screwing it in, that’s all it takes to start working afresh.

This spiral technology ensures the lowest possible tear out and is suitable for highly figured workpieces. The G0893 also features a 30-3/8″ by 6-1/4″ table, with special non-stick coating for smooth movements of the workpieces.

The 22.5 inch aluminum fence is adjustable and features 45 and 90 degree stops for optimum angle. What’s more, the 2 and half inches built-in dust collecting port ensures super convenient cleaning. It also comes with a large size dust bag and an adapter.

The overall powder-coated finish gives it the amazing look and solid feel. You will also get a couple of safety push-blocks. We were amazed by the fact that it packs all these features in only 56 lbs (approx. shipping weight) of stable, lightweight and portable design.

Specifications

- Motor: 120V-1.5 HP-12A-single-phase

- Max cut width: 6?

- Min cut length: 8?

- Max cut (per pass) depth: 1/8?

- Speed of cutterhead: 8,000 RPM

- Diameter of cutterhead: 1-7/8?

- Footprint: 19-½ inches x 11 inches

- Table: 30-? inches x 6-¼ inches

- Fence: 22-½ inches x 4-¼ inches

- Dust port diameter: 2-½ inches

- Shipping weight (approx.): 56 lbs.

Pros

- Spiral cutterhead

- Adjustable fence

- Coated table surface

- Built-in dust collector with collection bag

- Lightweight

Cons

- A bigger work table could house bigger workpieces

Our Verdict

Spiral cutter heads make jointing and planing work fun and super fast that help save time and effort. If you want to experience the difference, you can give this model a shot. We believe it will never disappoint you and will be worth every penny spent for it.

10 Cutech 40160H CT

Cutech 40160H CT is in the list and for real benefits. Its specs may outmatch the price. This portable jointer satisfies both beginners and professional woodworkers. Weighing 40 pounds, this is one of the most popular portable choices in the industry. You may not enjoy much stability from this machine as you would from a free-standing jointer, but you can still carry it anywhere or store it in your workshop when not in use.

This machine features a spiral cutterhead and double-sided HSS inserts that let you enjoy a perfect, quick, and efficient planing process. Upon your discovery that any of the inserts have become worn or blunt, you can easily turn it to reveal a new cutter and when the new face gets bad, you can get it replaced easily.

It comes with a motor that runs at a maximum speed of 11,000RPM. This is needed for precise, fast, and smooth cutting. Also, the table is sizable enough to help you plane small pieces of wood with ease. You can adjust the 30 x 6 3/16 size table to an angle for you to handle your project comfortably.

One of the things we liked about this model was its durable construction. It has a maximum cut depth of 1/8 inch which is the average for any benchtop jointer. It is amazing to know how easily you can tilt the fence to suit your needs.

The fence has dimensions of 19 5/8 x 4 3/8 and can be adjusted to angles from 90 to 135 degrees. The 2 ½ inch dust port helps to evacuate the chips and prolong the life of the knives.

Specifications

- Weight: 40 pounds

- Dimensions: 32 x 12.2 x 11 inches

- Color: black

- Motor: 10A & 120V

- Spiral cutterhead

- Cutter diameter: 2 inches

- Cutter speed: 11000RPM

- Table: 30 x 6 3/16 inches

- Dust port: 2 – ½ inches

Pros

- It comes with a spiral blade cutterhead

- It has an integrated dust evacuation system which makes it easy to clean

- It is easy to set up and use

- It produces a great finishing on the wood

Cons

- It is not suitable for hardwoods

- The table angle cannot be adjusted below 90 degrees

Our Verdict

If you have a limited workspace or you’re handling a light project, the Cutech 40160H-CT is exactly what you need. It can handle woods to a maximum length of 6-inches and the cast infeed and outfeed table can be adjusted to suit your needs.

The spiral cutterhead lets you handle a smooth and effective wood cutting operation. Finally, this budget-friendly, portable, and powerful model has enough in it to meet the versatile needs of the modern woodworkers.

11 WEN 6560

A great choice from Wen made from solid cast iron with the intention for meeting the desires of amateurs and professional users alike. It comes with amazing features despite its extremely low price.

One of WEN 6560’s main features worth considering is the cast iron material used in its fence, infeed table, and outfeed table. This solid body construction makes the machine stable and durable to take and joint heavy boards for hours.

The fence can be easily adjusted to angles of 45, 90, and 135 degrees respectively. Also, you can adjust your cutterheads using the adjustment knobs which makes it easier to align your workpiece to achieve a smooth and accurate cutting.

However, most of the adjustment knobs are made from plastic materials and they have the tendency to wear out much faster than other parts of the machine.

Still, on the design, the cutterhead features the popular double blade design which helps in simplifying its replacement and has a cut diameter of 6 1/8 inches. The WEN 6560 comes with a maximum speed of 10,000RPM to make it cut through soft or hardwood with precision and speed.

It comes with a maximum cut depth of 1/10 inches which makes it a little shorter than most of its competitors that maintains a cutting depth of 1/8 inches. It seems that the good thing about its shorter cutting depth is that it will take more turns before you can achieve a straight and perfect edge on thicker wood pieces.

Just like the 6560T, the 6560 also comes with a dust collection mechanism with a 2 ½ port directly connected to a filter bag that helps reduce the frequency of you emptying the bag. This system is very useful at keeping your machine clean and free from harmful dust particles.

Specifications

- Weight: 80 pounds

- Dimensions: 28 x 14 x 20 inches

- Fence dimensions: 22 ¾ x 4 ½ inches

- Cutterhead: 6 1/8 inches

- Table size: 6 ¼ x 28 ½ inches

- cuts per minute: 20,000

- Speed: 10,000RPM

- Warrant: 1 year

Pros

- The fence and tables are made from cast iron to enhance its durability and stability

- The cutterhead and fence can be adjusted easily

- It comes with a dust collection mechanism

Cons

- The plastic adjustment knobs tend to wear out too quickly

- It has a shorter cutting depth

Our Verdict

The WEN 6560 is the best bench jointer for smooth, flat and perfectly square joints out of your wood pieces. The base is made from cast iron to enhance its stability while removing the unwanted portions of the wood.

It produces 20000 cuts per minute to make it easy to work on your choicest projects. In addition, the table feed and fence are not only made from cast iron but can be easily adjusted to help you in removing the unwanted portions of the wood piece.

Benchtop Jointers Buying Guide: Important Factors to Consider

1. Size

Before you decide on the benchtop jointer to buy, you should consider the actual and normal size of the wood pieces you will be cutting. This will help you determine the right size for you.

The length of the knives determines the size of the jointer. This measurement is used to determine the maximum length of wood that the machine can handle comfortably.

However, a jointer can handle a wood which is double its bed’s length with ease. Therefore, bed lengths and blades are the two determinants of the size of a benchtop jointer and the wood piece it can handle.

The smallest jointer is the 6-inchsize which is perfect for home use and other professional applications. Also, they are portable, cheap and very easy to use. However, if you want to work on wood pieces with sizes that are larger than 6-inches, you must trim them first.

The next in line is the 8-inchsize benchtop jointer. These ones have a longer bed to handle big sized woods. But they’re a little expensive.

The biggest is 16-inch jointers. These are the free-standing ones and are suitable for large workshops and industrial applications. They are highly versatile with longer blades for the biggest sizes of wood.

2. Fence

Each model comes with a fence that facilitates efficient, quiet, and smooth operation. The positive stops help adjust the angles of the fence easily. The fence should be durable, rigid, and flat. Whether or not you will enjoy having a smooth plane depends on the flexibility of your benchtop jointer’s fence.

3. Power

You will also find models with motors having a power range from 1HP to 2HP. 1HP motors are powerful enough to let you plane boards easily. Also, single phase benchtop jointers which are to be used in your home should have a standard voltage of either 110V or 220V.

4. Build Quality

The material used in the construction of a jointer will influence its ease of use and durability. These tools come with tables made from cast iron that are sturdy enough to reduce the level of vibration and its impact on the user’s hands. This feature may increase its weight and make it a little uneasy to carry, but it is so beneficial to the user.

5. Cutterhead Speed

The speed of the cutterhead is expressed in cuttings per minute. As I said earlier, you need to feed the wood through the machine severally to obtain the perfectly smoothened edge. The greater the cutting speed; the faster you can complete your task. In most cases, you will notice that the cutterhead speed is twice the speed of the motor.

6. Cutting Blade

The cutting head type determines how the blade should be. Now, a machine with a spiral cutting head features a maximum of four blades and operates without noise. However, they are very expensive.

The most common jointers are the ones with a double blade. Moreover, these blades vary in quality and if you buy a poor-quality blade, you may have to replace them soon which will add to the operational cost of the machine.

7. Maximum Cut Depth & Rate

This rating determines how many times you will pass the piece of wood to obtain smooth edges. The calculation involves the rate of cut being determined by multiplying the number of blades with the cutterhead speed. The higher the maximum cut rate, the more effective the machine is. Also, the depth at which the machine penetrates the wood is influenced by its maximum cut depth. You should know that if the cut depth is large, it takes just a few processes to achieve the perfect surface.

8. Ease of Cleaning

You surely want a benchtop jointer that is easy to clean and maintain. These machines may churn out a lot of debris that you want to clear off. So, choose a jointer model that doesn’t present you challenges while removing the dust and cleaning the machine.

9. Dust Collection

The high-end models come with a dust collection system that sucks off the dust while keeping the work environment clean and free of allergens. Most dust collection systems vary by sizes and designs that determine how fast the wastes are vacuumed out or how frequently the dust bags can be emptied. You may want to consider a benchtop jointer with a large full-size dust collection bag which helps to reduce the rate at which you’ll be emptying the sag.

10. Jointer vs. Planer

As said earlier, jointers and planers are similar in terms of their purposes and functions but deliver different results. A planer serves better as you cut straight woods to equal thickness while benchtop jointers allow you to straighten the edges of a twisted or curved piece of wood. You will achieve a straight cut edge after a few runs through the blades. Full-sized jointers are made to perform the tasks of a jointer and planer.

11. Budget

Generally, benchtop jointers are more affordable than the regular free-standing jointers. However, you should not stop from spending some more bucks to buy a feature-rich product. Although the price may go higher than expected while the quality may not in all cases, you need to aim for a product with the best price-to-quality ratio.

Why Use a Benchtop Jointer?

A wood jointer helps you align one surface against another. It cuts pieces of wood that you feed through the blades. It is likely that you may have to repeat the process again and again until you obtain a smooth and flat-sized piece.

Benchtop jointers are compact and lightweight. So, they are more desirable than floor jointers for many woodworking projects. This portability lends this type versatility which is unavailable in the floor type. It performs typical functions, such as flattening, straightening, and smoothening wood pieces.

This power tool is commonly used by woodworkers to square and true boards. These machines are available in different sizes which determines the size of wood that it can accept.

Who Needs This Tool & How It Works

A bench top jointer works by feeding the piece of wood over the blades of the machine from an infeed table. As the wood passes between the blades, it is shaped to create a smooth and flat edge. It is suitable for beginner woodworkers who desire to enhance their joinery skills and for professionals who want to increase their speed and enhance accuracy.

Planing is one of the typical woodworking operations. This device will help you to create points for other cuts and measurements effectively. If you want to get a smooth and straight wood surface without having to pass through the rigorous task of using the hand planer, you need this tool. Having bevel cuts is an amazing outcome a standard jointer provides. However, you may need extra cautions to perform this with your tool.

Care & Maintenance

Caring for and maintaining your benchtop jointer will help to prolong its life while keeping you and your work environment safe. Moreover, you will save some money if you adhere to the maintenance tips that the manufacturer provides since your time of visiting the shop for replacement parts or new machines will be reduced.

Strictly adhering to the following tips will help you enjoy your machine for long.

- Be sure that your cutting knives are in good condition

- Don’t try to join boards that are smaller than 12 inches

- Keep your machine clean and free of dust

- Empty the collection bag immediately it is full

- Ensure that the infeed and outfeed tables are aligned properly

Usage & Safety Tips

These essential woodworking tools are designed to produce a smooth, flattened and accurate edge on wood surfaces while allowing you to operate easily and comfortably. Despite that, each machine is designed with your safety in mind, you have a responsibility to keep yourself and the machine safe by following these simple rules.

- Secure your jointer by bolting it to a wall. This will help keep it stable and reduce the impact of vibration.

- Adhere strictly to the instructions that are provided on the machine’s manual

- If you’re not qualified to handle the task, don’t attempt it

- Protect your eyes by wearing safety goggles

- Keep your workspace clean and free from hazards

- Store the machines safely and keep them from the reach of children

- Let all your attention be on the job

- Never misplace the importance of the guard

- As the board passes through the machine, keep your hands away from the back

- Using push blocks will ensure that your hand and the cutter at least 6 inches apart

- Ensure that you set the cutterhead based on the thickness of your wood

- Stay at one of the sides of the jointer and not behind

- Allow the cutterhead to reach its maximum speed before you insert the wood

A Word from Drillly

Here we have provided you with a shortlist of the top benchtop jointer choices of today to help make your shopping easier.

There are many of these products from popular brands like Craftsman, Ryobi, Wahuda Tools, Vevor, and many more. But you should consider the basic factors like your budget, workshop size, and ease of maintenance among other things before deciding on a particular model.

Our top pick – the Cutech 40160H-CT – is portable, compact, and features easily replaceable HSS inserts. This is one of the best jointers for the money.

Another product featured in our benchtop jointer reviews is the Jet JJP-10BTOS which is extremely versatile. It can serve as a planer and jointer with high-quality performance. Moreover, it can handle both small and large sized woods with ease. Though it is a bit pricey, its amazing features make it worth every penny.

We are confident that you will find this review useful and be able to make a really good choice.