Cutting concrete and asphalt is a tough job that requires utmost accuracy, ability, and patience. You also have to deal with the fact that you only have one chance at the cut or you have to start the whole process again. This means you’ll need a concrete saw that is powerful and precise.

A concrete saw can cut more than you think and comes in different types and sizes. We carefully singled out and reviewed today’s safest and most functional consaws.

See which one suits your DIY or worksite needs!

Top 10 Best Concrete Saws We Tested and Ranked

01 Husqvarna 967181002 K760 II 14 inch (Editor Choice)

Topping today’s list is the Husqvarna 967181002 K760 II 14-inch Gas Cut-Off Saw. It features one of the most powerful motors on our list providing supreme ease of cutting even against the hardest of surfaces. It is also one of the most convenient and stress-free cutting tools on the market.

The K760 has a powerful 2 stroke engine that delivers up to 9,300 RPM. It also has a 0.9-liter fuel capacity for longer jobs. Despite this, the K760 is ergonomically designed and limits vibrations for less stress, even when cutting through harder substances like steel.

This dustless power tool also has a Dura Starter feature that ensures a quick start, as well as improved air filtration to prevent dust from getting into the tool. This ensures that the K760 will last a long time, even with minimal care and maintenance. The automatic water shutoff is also a great feature for this product to minimize wastage as well as for additional convenience.

For its price point, the Husqvarna K760 is the best that you can get if you want to have a tool that will serve you in the long term. It is capable of deep cuts of up to 6 inches and has a higher power-to-weight ratio compared to other products that offer the same type of power under the hood. This makes for a flexible tool that can keep up with any type of job both for novices and professionals alike.

Specifications

- Wet or Dry? Both

- Power Source: Gas

- Blade Diameter: 14 inches

- Hand Held or Walk-Behind? Hand Held: Hand Held

- Depth of Cut: 6 inches

- RPM: 9,300

- Weight: 26 lbs

- Size: 24 x 12 x 12

Pros

- Light even with a filled up tank

- Minimizes and limits vibrations even under heavy duty use

- Very easy to start

- Can easily cut through hard substances with its powerful motor

- Can cut up to 6 inches deep

Cons

- The price may be too steep

- Not recommended for indoor use

Our Verdict

The Husqvarna 967181002 K760 II 14-inch Gas Cut-Off Saw is a beast of a machine that can be up to the heaviest of tasks. It can cut through concrete like butter, and it is comparatively lightweight for the power that it brings. It also handles quite well with its ergonomic design and low vibration.

For wet cutting outdoors, you can’t get any better than this tool. If you have the budget for it, then make this your top priority purchase as it is something that you would not regret.

02 Evolution DISCCUT1 12-Inch Disc Cutter (Budget Choice)

One of the cheapest concrete saws that you can find in today’s market is the Evolution DISCCUT1 12-Inch Disc Cutter. Priced at a little over 200 dollars, this product is an absolute steal, especially as it’s capable of making cuts of up to four inches with a 12-inch blade attached.

The Evolution DISCCUT1 was created with ease of use in mind. This concrete hand saw requires very little maintenance aside from external cleaning, and its ergonomic design allows for accurate cuts both horizontally and vertically. Its 15Amp motor provides amazing ease in cutting, and the DISCCUT1’s spindle lock mechanism makes changing blades a breeze.

With such a low price for a powerful and elegant designed tool, you can expect that there are some shortcomings along the way. The Evolution DISCCUT1 is designed from dry cutting, so you can expect cooling periods as well as a very dusty work area.

There are also no adjustments available for the cutter, so you would have to make do with guard adjustments in order to get the depth that you want. Otherwise, expect uneven cuts to occur as you are using a sophisticated type of saw, not a simple one.

Still, the Evolution DISCCUT1 is a great no-frills saw that delivers plenty of power. It is also very simple in design, so even novices can greatly appreciate its capabilities. As they say, it is not the tool but he who wields it, and the DISCCUT1 definitely fits the bill if you want something that is not expensive but is still capable of getting the job done.

Specifications

- Wet or Dry? Dry

- Power Source: Electric

- Blade Diameter: 12 inches

- Hand Held or Walk-Behind? Hand Held

- Depth of Cut: 4 inches

- RPM: 5,000

- Weight: 21 lbs

- Size: 19 x 22 x 15

Pros

- highly affordable

- Designed for safety and convenience

- Can provide very accurate cuts

- Requires little maintenance

- Blades can be replaced easily

Cons

- Not recommended for wet cutting

- Cuts cannot be adjusted easily

Our Verdict

Definitely, the greatest thing about the Evolution DISCCUT1 12-Inch Disc Cutter is its price. Nowhere can you find a cheap concrete saw that can do what the DISCCUT1 can. It is also a great beginner’s saw as it is easy to handle and requires almost no maintenance.

However, nuances may occur doing jobs due to dust. The tool has also been known to trip breakers so make sure that you have an adequate electrical supply and wire to operate this workhorse.

03 Husqvarna 966799401 K3000 Wet Cutter

Despite being categorized as a wet concrete saw, the Husqvarna 966799401 K3000 Wet Electric Power Cutter can actually function dry. In fact, a vac unit may be unit so that emitted dust can easily be sucked in. On the other hand, under the wet cutting mode, water can be regulated so that slurry production is minimal.

The Husqvarna K3000 can accept both 12 and 14-inch blades and is pretty lightweight. In addition, spindle locks allow for quick replacement. Unfortunately, the K3000 falls a bit short when it comes to power, with only a 4,500 RPM capability with no load. As such, the tool falls short quite significantly, especially when compared to gas-operated tools within a similar price point.

Despite this, the 2.4 horsepower motor is accentuated by the K3000’s unique forward rotation. This – along with the tool’s ergonomic design – makes for a much easier cutting experience despite the low base power that it has. Low power also means minimal vibration and minimal noise, making the Husqvarna K3000 a great tool for work both indoors and outdoors where excess noise may become an issue.

As such, the K3000 proves to be one of the best in its class, especially when it comes to operating ease and convenience as well as post work cleanup. This concrete saw from Husqvarna is a great tool to have when using a gas-powered saw just won’t cut it, in a metaphorical sense. Be prepared to shell out a thousand dollars or so for this model, though.

Specifications

- Wet or Dry? Wet

- Power Source: Electric

- Blade Diameter: 14 inches

- Hand Held or Walk-Behind? Hand Held

- Depth of Cut: 5 inches

- RPM: 4,500

- Weight: 21 lbs

- Size: 22 x 16 x 5

Pros

- Perfect for indoor jobs

- Lightweight

- Easy to replace blades

- Switching between wet and dry cutting is ease

- Advanced overload protection

Cons

- At least a 20 amp breaker is required

- Price vs. power ratio is high

Our Verdict

The Husqvarna 966799401 K3000 is a wet concrete cutting saw that’s worth your attention. Although this can easily change to dry cutting mode within just a few minutes if wet cutting is not possible.

Despite its high price point and low relative power, we can safely say that the Husqvarna K3000 more than makes up for it with its no-mess operations and minimum maintenance. If you have the budget for it, then get this for your light indoor jobs that don’t have tight man-hour requirements.

04 Makita EK7651H 14 Inch MM4 4 Stroke

For gas power concrete saws, the Makita EK7651H is a machine users cannot ignore, especially when it comes to power and convenience of use. It boasts a 4.2 horsepower engine that can saw through even the hardest substances with minimal effort, and noise levels are quite forgivable at 92.7dB given the power of this tool. The cutting arm is also adjustable, allowing you to cut under different positions and situations the best way possible.

The MM4 is also not a gas guzzler as it consumes only less than a gallon per hour. Reduced exhaust will guarantee fewer fumes which makes it suitable for indoor work despite being gas-powered, and the tool also allows for, among other features, less carbon buildup which can greatly lengthen its lifespan.

The Makita MM4 includes a water tank that, along with its fuel tank, is detachable and can be replaced and customized according to your needs. However, perhaps the MM4’s most interesting feature is that it does not require oil mixing, so you can simply fill up the tank and let it rip in one go.

One downside of the Makita MM4 is that the design is more complicated as compared to the usual 2 stroke gasoline-powered concrete saws commonly available for sale. This makes for a slight learning curve for those not familiar to the mechanisms involved.

However, the user manual and the accompanying tools will make changing filters and making repairs a bit easier, even for those not familiar with 4 stroke engines.

Specifications

- Wet or Dry? Wet

- Power Source: Gas

- Blade Diameter: 14 inches

- Hand Held or Walk-Behind? Hand Held

- Depth of Cut: 6 inches

- RPM: 9,100

- Weight: 28.4 pounds

- Size: 28 x 12 x 19

Pros

- No oil mixing required

- Highly fuel efficient with less exhaust emission

- The first concrete cutter with a 4 stroke engine

- Improved filtration systems for better durability

- Easily adjustable cutting arms

Cons

- Can be too expensive for some people

- Can be too complicated for novices

Our Verdict

The Makita EK7651H 14-Inch MM4 4 Stroke Power Cutter provides ample power even for heavy duty jobs for commercial or industrial cutting. It has a powerful enough motor and safety features are integrated into the product for accident prevention and minimization of fatigue.

As with most products carrying the Makita name, expect top-notch durability and length of service with the MM4, although it should be expected that a higher level of care and maintenance is required in order to assure that it keeps quality performance for years.

05 Makita 4100KB 5 inch Dry Masonry Saw

Boasting a 13 Amp motor capable of providing 12,200 RPM, the Makita 4100KB 5″ Dry Masonry Saw, with Dust Extraction tops our list for dry concrete cutters. It is perfect for quick thin cutting jobs such as for tile and concrete slabs, as it can cut through those apart like paper.

The Makita 4100KB utilizes 5-inch blades with a 13/16” arbor size. This limits the cutting capabilities of the tool, especially if you want deeper cuts. However, precision and accuracy cannot be matched due to its depth gauge lever and the optional guard rail. You’re definitely going to be limited by how deep it can cut through; i.e., less than 2 inches even when fully extended.

What really sets the 4100KB apart from other similar concrete saws is its dust extraction port which can get almost all dust emitted from cutting. This makes cleanup of dust an absolute snap, and can definitely increase safety conditions as well as convenience.

This tool features a transparent upper guard dust cover and dust protected cover which prevents excess dust from getting into it. This allows for continuous use with minimal requirement for care and maintenance.

Its light weight and small size make it very convenient to carry around. Makita 4100KB is a great indoor tool to have around, especially if you intend to be mobile. However, this is definitely not a one size fits all piece of equipment as deeper cuts will surely require bigger tools.

Specifications

- Wet or Dry? Dry

- Power Source: Gas

- Blade Diameter: 5 inches

- Hand Held or Walk-Behind? Hand Held

- Depth of Cut: 1.5 inches

- RPM: 12,200

- Weight: 6.6 pounds

- Size: 11 x 14 x 8.2

Pros

- Very compact

- Can suck up dust for cleaner cutting work

- Optional guard rail for more accurate cutting

- Comfortable to use

- Powerful motor

Cons

- High price to power ratio

- The guide rail is an additional purchase

Our Verdict

If you are looking for a dry concrete saw that requires little maintenance and cleanup of both equipment and work area, then the Makita 4100KB 5″ Dry Masonry Saw, with Dust Extraction should be one of your top choices. It is very simple to use, and cleanup is a snap with its extraction port attachment.

While a bit pricey, you can save up a lot of time for cleaning up. Cuts are also much more accurate as compared to others, although an additional investment is required.

06 SKILSAW SPT79A-10 7 inch Walk Behind Worm Drive

If you are looking for a walk-behind concrete saw, then look to further than the SKILSAW SPT79A-10 7″ Walk Behind Worm Drive for Concrete. Using this beast will literally feel like a walk in the park with its powerful 15 Amp, 5,100 RPM motor that can cut through almost anything with minimal effort.

The SKILSAW SPT79A-10 is extremely lightweight and portable as it weighs only 31.7 pounds. It also has an adjustable handle and pointer for convenient and precise cuts. This, along with beautifully designed foot plates and wheels will provide you with ease of use that you will surely love. Of course, cutting floors will now be a breeze as this is a walk-behind.

The SKILSAW SPT79A-10 is also beautifully constructed with rust-resistant components that will assure that it will keep its pristine condition even with minimal care. This is especially important as this tool was created with wet cutting in mind.

One of our gripes about the SKILSAW SPT9A-10, however, is that although the package comes with a vacuum adapter, dust management is actually not integrated and you would have to purchase a separate system for it. Still, it’s a small price to pay for a great product that you can use both inside and out.

The SKILSAW SPT79A-10 accepts 7-inch diameter blades with a 7/8” arbor size. The maximum depth of cuts is at 2 inches and is adjustable based on your needs. As for pricing, the SKILSAW SPT79A-10 is being offered at an acceptably modest price. In any case, the convenience of having a walk-behind concrete saw is definitely worth what you’re paying for.

Specifications

- Wet or Dry? Wet

- Power Source: Electric

- Blade Diameter: 7 inches

- Hand Held or Walk-Behind? Walk-Behind

- Depth of Cut: 2 inches

- RPM: 5,100

- Weight: 31.7 pounds

- Size: 31.5 x 11.4 x 11.8

Pros

- The handle can be adjusted and folded for easier storage

- Rust-and corrosion-resistant

- Oversized wheels for more stable cutting

- Easily affordable

Cons

- Can get very dusty when dry cutting without a vacuum attachment

- Usable for floorings only

Our Verdict

The SKILSAW SPT79A-10 7″ Walk Behind Worm Drive for Concrete combines power and elegance in one compact package. This is simply the best walk behind concrete saw that you can look for, with its lightweight design and ample power to cut through tile or asphalt flooring with ease. You don’t have to worry about sharpening the drill bit what you have to do while working with a drill press.

It can also quickly switch between wet and dry cutting, although wet cutting is definitely preferred; especially if you don’t have a vacuum attachment handy.

07 Makita 4114X 14-Inch Angle Cutter with Diamond Blade

The Makita 4114X 14-Inch Angle Cutter with Diamond Blade is a workhorse of an electric concrete saw despite its small size. Its 15 Amp motor is capable of delivering 3,500 RPM and can cut up to a depth of 5 inches, especially with the default diamond blades attached. Also, as the name implies, the Makita 4114X Angle Cutter can really cut close to corners as the tool base can be removed so that it would not block your cutting angle.

The Makita 4114X also comes with attachments so that you can plug in a water hose for wet cutting as well as a vacuum for dust management. However, our tests have shown poor dust collection as the tube was small. As a result, a lot of dust still remained even with a high powered vacuum attached.

For the tool itself, the Makita 4114X has rubber shielding which prevents dust from getting into critical components. You can also feel the sturdy quality which has been the trademark of Makita since the early days despite its light weight. The Makita 4114X also protects itself through its patented SJS Technology that prevents gear damage.

The Makita 4114X worked well during our tests with both dry and wet cutting. The tool is easy to handle, especially with the tool base removed; making it great for working up close even at odd angles. For close quarter cutting jobs that need some serious power, you can’t go wrong with the Makita 4114X in your tool cabinet.

Specifications

- Wet or Dry? Both

- Power Source: Electric

- Blade Diameter: 14 inches

- Hand Held or Walk-Behind? Hand Held

- Depth of Cut: 5 inches

- RPM: 3,800

- Weight: 23.6 pounds

- Size (inches): 26.5 x 1 x 1

Pros

- Can work with both AC and DC power

- Has a vacuum attachment port for dust management

- Can cut up to 5 inches deep

- Can be used both wet and dry cutting

- Tool base can be removed for close cutting

Cons

- Can be quite heavy especially when used continuously

- Dust management is not that good

Our Verdict

The Makita 4114X 14-Inch Angle Cutter is an excellent companion and is very flexible to your cutting needs. While there are some concrete saws that offer more power for the same price, a few can match the Makita 4114X’s maneuverability in the field.

Built-in attachments make preparations for wet and dry cleaning a snap, although there is something to be said about dust management for this particular model. That said, this tool still performed amazing based on our test and research just like the DPC7311.

08 SKILSAW SPT79-00 15-Amp MEDUSAW Worm Drive Saw

If there is a criterion for the prettiest concrete saw, then the SKILSAW SPT79-00 15-Amp MEDUSAW Worm Drive Saw for Concrete would probably take the cake. It’s not about beauty, however, and the MEDUSAW can certainly compete when it comes to performance as well.

Driven by a 15 Amp dual field motor that protects the tool while still delivering power, the SKILSAW MEDUSAW is capable of cutting up to 2 inches in depth using 7-inch disc blades. Expect operations to slow down as you go deeper, though, as tests show that its optimum depth is around an inch or so.

Few come close, however, to its precision but when it comes to straightness and depth. Multiple features are included within the MEDUSAW to ensure that cuts will come out just the way that you want it. These include Cut-Ready adjustable plunge locks and front pointer guides as well as foot wheels.

MEDUSAW also features CFGI protection and rust resistance, allowing you a worrisome wet cutting session as you would not have to worry about electrical shocks or corrosion. Dry cutting will also be a breeze with the MEDUSAW as testing showed promising results when using the vacuum port with a decently powered vacuum. There was virtually no dust flying around, and you can potentially work indoors without a dust mask if this beauty is on the task.

The MEDUSAW closely resembles a walk-behind and you can pretty much use it in that way, making this one of the most versatile and multipurpose concrete saws on our list.

Specifications

- Wet or Dry? Both

- Power Source: Electric

- Blade Diameter: 7 inches

- Hand Held or Walk-Behind? Hand Held

- Depth of Cut: 2 inches

- RPM: 5,100

- Weight: 16.9 pounds

- Size (inches): 19.5 x 7.8 x 7.5

Pros

- Very lightweight

- Highly adjustable for precision cutting works

- Offers GFCI protection to prevent electric shocks

- Rust resistant

- Ports for both water and dust

Cons

- You can get cheaper concrete saws with the same specifications

- Works slower on deeper cuts

Our Verdict

The SKILSAW SPT79-00 15-Amp MEDUSAW Worm Drive Saw for Concrete is beautiful outside, but performs just as well during our testing sessions. While it won’t be beating SKILSAW’s walk-behind model any time soon, you can definitely use this for floors as well as walls, regardless of the surface.

Of course, cutting depth should also be a consideration. But if you could only buy one tool for making shallow cuts among any other possible choices, this should definitely be on top of your list.

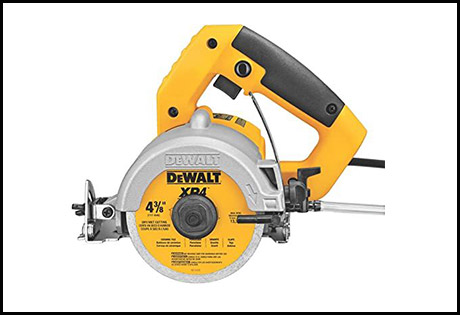

09 DEWALT DWC860W Wet/Dry Masonry Saw

Those who want a small and light hand concrete saw would definitely love the DEWALT DWC860W Wet/Dry Masonry Saw. It is absolutely light and requires very little strength to cut through cement and tile with its powerful 10.8 amp motor. What’s even great is that it costs less than 200 dollars, making it one of the cheapest in our list.

Cut depths can be easily adjusted using bevels up to 45 degrees, and a lock-on button is available to reduce stress for prolonged and continuous cutting. It also has a waterline connection available, but this can be shoddy at times. You may need to do some modifications in order to keep the hose from detaching or breaking to get the most out. In any case, the DWC860W can perform dry cutting quite well.

DEWALT 4.5 inch blades are recommended for this tool, although some brands also fit. Its small arbor size limits its potential, however, making this particular product capable of only a handful of tasks. There’s a lot of other concrete saws that can do much more than the DWC860W, but its price point and lightweight design is simply too enticing to pass up especially if you have a couple of hundred dollars to spend.

If you want a specialized tool that you will be used specifically for cutting thin slabs with ease, and if you don’t mind dry cutting or adjusting the water hose from time to time, then the DEWALT DWC860W is the tool for you.

Specifications

- Wet or Dry? Wet

- Power Source: Electric

- Blade Diameter: 4.5 inches

- Hand Held or Walk-Behind? Hand Held

- Depth of Cut: 1.5 inches

- RPM: 13,000

- Weight: 9 pounds

- Size (inches): 6.9 x 10.3 x 9.8

Pros

- Great for precise cuts

- Highly affordable

- Features a very powerful motor for its size

- Lightweight

- Comfortable to use

Cons

- Limited when it comes to cutting depth

- Water cut-off assembly feels cheap

Our Verdict

The DEWALT DWC860W 4-3/8-Inch Masonry Saw is pretty light both in design and price. Unfortunately, it is also light in terms of capabilities, despite being durable enough to cut through rock and granite.

This tool is great for light work such as cutting up tiles or for regular DIY jobs at home. However, it cannot keep up with the big boys when it comes to bigger tasks. Despite this, the DWC860W can still serve its purpose and can be a handy tool to have around for easy enough jobs that do not require bigger saws to handle.

10 Husqvarna Gas Cut-n-Break Power Cutter K760

The Husqvarna Gas Cut-n-Break Power Cutter is a monster of a machine for those who want to make quick work of cutting jobs. The Cut-n-Break offers a 5 horsepower that does not guzzle down gas and emits fewer fumes. It also has the patented Easy Start and Dura Starter features common with Husqvarna tools which provide not only ease of use but also prevention of wear.

But its most excellent feature is its dual-blade function, which allows for cuts that can easily be broken with the built-in breaking tool. Intermittent cutting will also allow the tool to reach in and cut up to 16 inches deep, making it worth being listed here without being a chainsaw.

This tool is ideal for making entryways, trenches, and practically anywhere that deep cuts are required. Wet cutting and air filtration systems ensure that dust is not much of an issue when it comes to the tool and personal safety.

Specifications

- Wet or Dry? Both

- Power Source: Gas

- Blade Diameter: 9 inches

- Hand Held or Walk-Behind? Hand Held

- Depth of Cut: 16 inches

- RPM: 9,300

- Weight: 31 pounds

- Size (inches): 31 x 9.68 x 17.56

Pros

- Has one of the most powerful motors around

- Offers one of the deepest cuts in the market

- Can make quick work of cutting jobs

- Starts very easily

- Fuel-efficient

Cons

- High price

- Single blade not usable

Our Verdict

The Husqvarna Gas Cut-n-Break Power Cutter is great for making deep cuts without having to buy or rent a chainsaw. It is very resilient and can easily be adjusted for varying cuts just like other Husqvarna products like K12, K770, K750, K700, K3000 or K4000. Although its length may leave something to be desired especially when space issues are considered.

Still, if you want a disk cutter that can pretty much serve as a chainsaw from time to time, then the Husqvarna Cut-N-Break is what you should consider.

Understanding Concrete Saws – What are They?

Simply put, a concrete saw is a tool used for cutting concrete. However, the purpose does not stop there because there are consaws that can also be used to cut other hard substances such as asphalt, bricks and tiles, while some can even cut through steel. This is essential for those involved in precise cutting jobs, such as construction or landscaping. So, start using a concrete saw if your job demands that.

There are many different kinds of concrete saws available, ranging from portable suitable for thin surfaces and light work to the heavy duty ones powered by gas or pneumatic or hydraulic pressure. There are also handheld and walk-behind types, the latter of which is more suited for areas with ample space to work and for those who prefer the convenience and ease in cutting. You will also find self propelled, early entry, and concrete ring saws in the industry.

In addition, different variations of blades are available and each is especially suited based on your preferences as well as on budget and performance concerns, ranging from corundum masonry to reciprocating to diamond/metal composite blades used for either wet or dry cutting.

Things to Look For in an Ideal Concrete Saw

1. Wet or Dry

Some blades are required to be wet during use as this will lubricate the blades when cutting. This will help in prolonging the life of your blade as well as prevent accidents due to segments snapping off. Wet blades also help in minimizing dust generated.

Dry blades, on the other hand, are used when no water source is available within the immediate vicinity. The dry cutting means that blades would tend to overheat more, and a preventive measure for this is to make intermittently deeper cuts to prevent premature damage to the blades. Also, it is important to have proper ventilation and housekeeping within the area when dry cutting due to more dust being produced.

2. Chain Saws or Disc Cutters

In our opinion, the only reason that you would employ chainsaws is if you would require much deeper cuts, usually at around 14 inches or so. Disc cutters are definitely more precise when it comes to flush cutting and relief joints, and chainsaws are more delegated to removal works rather than construction. Still, this is something worth exploring depending on the job you are up against.

3. Gas or Electric

A gas-powered concrete saw provides more cutting power. However, noise and fumes may become an issue, especially in enclosed and unventilated areas. Like battery powered chainsaws, an electric cement saw is much quieter and there are no harmful gas fumes to consider. Power limitations may be an issue though since harder surfaces as well as substances like hardwood may be more difficult to cut.

As for portability, while there are models that are quite lightweight even for those that require gas or batteries. We have included electric and gas concrete saw reviews here so you can decide which type to go for.

4. Handheld or Walk Behind

The choice between a handheld concrete cutter or a walk behind will depend on both convenience and portability. The former allows you to make cuts that are not straight or are already fixed while the latter can only be used for straight cuts on surfaces that you place on the floor. On the other hand, nothing beats the walk behind type when it comes to ease and convenience of use.

5. Arbor Sizes

The arbor size pertains to the size of the hole that the disc blades would attach to. Larger arbor sizes can accept smaller blades with the right type of bushing, while smaller arbor sizes can only accept blades of limited arbor hole sizes. As a safety precaution, you should never attach blades that do not fit snugly as the blade might move around during cutting, which might cause uneven cuts or, worse, accidents in the workplace.

6. Disc Blades

There are different blade qualities, ranging from carbide to diamond tipped ones. Blades are abrasive in nature and tend to wear down after use. Of course, more durable ones will tend to cost more.

Different concrete saws require different diameters of blades. A small concrete saw, for example, would typically require small blades of 4.5 to 7.25 inches in diameter.

7. Depth of Cut

Only high-quality concrete saws will allow you to adjust the depth of your cut. Of course, the total diameter of your blade would also be a factor. Typically, the bigger the saw, the deeper it can cut.

Concrete saws usually have a knob or a level that you can use to adjust the cutting depth. Set it up and make sure that it’s locked in place for even cutting.

| Cured Concrete/Asphalt Blades | |||

| Diameter | Cutting Depth* | ||

| 12″ | (305mm) | 4″ | (102mm) |

| 14″ | (356mm) | 5″ | (127mm) |

| 18″ | (457mm) | 7″ | (178mm) |

| 20″ | (508mm) | 8″ | (203mm) |

| 24″ | (610mm) | 10″ | (254mm) |

| 26″ | (660mm) | 10-5/8″ | (270mm) |

| 30″ | (762mm) | 11-5/8″ | (295mm) |

| 36″ | (914mm) | 14-3/4″ | (375mm) |

| 42″ | (1067mm) | 17-3/4″ | (451mm) |

| 48″ | (1219mm) | 20-3/4″ | (527mm) |

| Green Concrete Blades | |||

| Diameter | Cutting Depth* | ||

| 6″ | (152mm) | 2″ | (51mm) |

| 7″ | (178mm) | 2-1/2″ | (64mm) |

| 8″ | (203mm) | 3″ | (76mm) |

| 10″ | (254mm) | 3-3/4″ | (95mm) |

| Hand-Held High Speed Blades | |||

| Diameter | Cutting Depth* | ||

| 4″ | (102mm) | 1″ | (25mm) |

| 5″ | (127mm) | 1-1/2″ | (38mm) |

| 6″ | (152mm) | 2″ | (51mm) |

| 7″ | (178mm) | 2-1/2″ | (64mm) |

| 8″ | (203mm) | 3″ | (76mm) |

| 10″ | (254mm) | 3-3/4″ | (95mm) |

| 12″ | (305mm) | 4″ | (102mm) |

| 14″ | (356mm) | 5″ | (127mm) |

8. Safety

Some concrete saws have safety features that offer protection to its users. Safety guards, dust filters, and voltage protection are just some of the features that you can find. Safety certifications and both international and national standards are sometimes provided to ensure quality and safety of products.

9. Efficiency

The efficiency of slab saws depends on its power as well as the quality of the blades. The higher the RPM and power of the motor, the easier that you will be able to make cuts. High-quality blades will also make cutting easier and faster with little to no pressure required.

However, make it a point to let the blade rest after prolonged cutting to prevent it from overheating. This is especially important when using dry cutting blades. In any case, an efficient cutting saw can help you save a lot of man-hours, which translate to both cost and time as well as effort.

10. Convenience

Convenience pertains to ease of use when carrying or operating your road saw. This can include weight, vibration, noise, maneuverability, and even the length of the power cord. Having a concrete saw that is convenient to use will save you not only time, but it will lessen the strain of operating it as well.

11. Cost

Concrete saws have different price ranges from a couple of hundred dollars to several thousands. This will depend on the size and power of your selection, and some brands are also known to be more expensive than others.

Should I Buy or Rent a Quick Cut Saw?

Buying a concrete saw is a big decision, as you would be stuck with it for a long time. For one-time jobs that require a specialized tool, renting would be the right call. This is more economical and practical, especially if you will not be using it consistently.

However, purchasing a concrete saw is your bet if you are in a landscaping or construction business, as well as if you are doing a lot of DIY work. A frequently used saw that you have bought pays for itself in a couple of months, and with proper care and maintenance, a concrete saw can last you for many years.

You should check on your specific needs and budget to decide whether to buy or rent. In any case, having a cheap concrete saw, at the very least, as a part of your toolkit is an absolute essential while renting or buying specialized or heavy duty ones should be decided based on the circumstances mentioned above.

Safety Tips

Whether your concrete saw is the walk behind or handheld or chop saw type, make sure that you take proper precautions to avoid damage to your property or injury to yourself. It is very important to read the operations manual of your tool before its use. Never forget to wear proper protective equipment such as gloves, dust masks, steel-toe shoes, and eye goggles when operating these types of equipment.

It is also very important to prepare your work area before using a concrete saw. For wet cutting, make sure that you have an adequate water source and water would not reach electrical outlets or other liquid sensitive equipment. Make it a point to keep any electrical wires away from the work area, and that the surroundings are well-lit and properly ventilated.

Lastly, keep others away when the concrete saw is in operation, especially children and pets, and never operate an improperly acting machine without having it checked by a professional first. Always focus on the job at hand when operating any type of similar equipment and never handle such a potentially dangerous device without the utmost care.

Care & Maintenance

Maintenance of your demo saw is actually simple and if done properly, your tool can serve you well for many years. However, as such equipment do take a lot of abuse, regular checkups must be done to ensure that they remain in a good condition even with regular use.

Make sure to regularly clean all external surfaces and lubricate bearings as needed since sludge and water buildup can drastically affect your concrete saw’s performance. Make it a part of regular maintenance to check on air filters, belts, and oil levels. Change your saw’s oil as indicated in the user’s manual, and replace faulty parts as needed.

Another thing that you should do is ensure that you are using the right blades for the job. Replace your blades once worn out to reduce the stress on your saw. Make sure that you check your saw before using it, and have it checked out if anything does not feel right as using it further may cause more damage and might even lead to accidents or injury.

Summing It All Up

We shared the best concrete saws available today so you can make an informed buying decision. Personally, I’d choose the SKILL SAW MEDUSAW for shallow cuts and the EVOLUTION DISCCUT1 for everything else.

This is based my criteria on my own needs and budget, which might, of course, differ from yours. My choices were made due to my personal disdain of gasoline fumes, as well. For other jobs outside the scope of these two, then I’d probably just rent as seldom do those types of jobs come in anyway.

Aside from these, there are also reputed brands offering high performance concrete saws like STIHL (GS 461), Core Cut, Harbor Freight, Milwaukee (M18), AGP Europe, Perfect Trac, Echo, Edco, Bosch, Dolmar (309), Redzaw, Norton, Hilti (DSH 700 & DSH 700-X), Wacker Neuson, Multiquip (Slab Saver), Husky, Dimas, Hitachi, Norton, Diesel, Meco, Mongoose, Homelite (MP38), and Partner (K950 & K1200). But we could not list their products here simply because they were not good enough when we made the comparison.

Still, it is more a matter of personal taste in the end, as well as the nature of the job at hand. By knowing what each of these concrete saws can do along with their limitations, you will know for sure which one to get.

FAQs

Q. Can I cut concrete with a circular saw?

Ans. Yes, you can if the concrete is only 2 – 3 inches thick. Don’t forget to get a decent blade, safety glasses, a respirator mask, and a box fan with a furnace filter because there will be a lot of dust to ward off.

Q. Is using water really necessary when sawing concrete?

Ans. Yes, it is because water helps reduce airborne dust and acts as a lubricant and coolant for the diamond blade.