Activities like drilling, sawing, gluing, and sanding are nothing new to a DIY individual/professional, even with the least amount of experience in metal/woodworking; hence the need for holding the object (workpiece) stationary to allow for smooth and uninterrupted operation.

A vise is always a welcoming tool for any wood shop or metal shop, and for the DIY enthusiasts, hobbyists, and pros that don’t want an exception to the rule of accuracy and precision on whatever they work on. But the question here is, how will you identify the perfect bench vise that supports your individual needs?

Well, we’ve reviewed a number of bench vises on the current market and personally tested them to prepare this list. We are confident that this review and buyer’s guide will help you find your right match so you don’t have to go through such a painstaking process for the same purpose. Read on and see which one to bring in to your metal shop or woodshop!

Our Reviewed 10 Best Bench Vises

Here comes our final list of the most exclusive bench vise choices that you might find in today’s market.

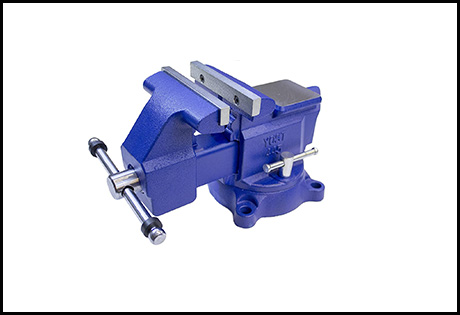

01 Yost 465 6.5-inch Combination Pipe & Bench Vise (Our Top Choice)

Our reviewers settled for Yost Vises 465 as the top of all and numerous factors influenced this decision.

First, the blue die-cast iron vise is a piece of versatile equipment. It can manipulate both pipes and metal sheets. It’s a little heavy but handles the low-intensity tasks pretty efficiently. You don’t need another vise to grip a steel pipe or a metal sheet since it performs these functions well.

Its strength comes from the full 6.5” jaw width that makes it aptly hold all light duty projects. Further, it secures a pipe with the dimensions being 0.125? to 2.5?.

With this specific model, hammering, as a job, becomes easy. It features an anvil portion on top beside the standard additional worktop. Its top jaws are flexible while the grooved stationary jaws provide a firmer clamp.

The mainframe uses cast iron materials and the U channels bars use steel. It measures just 15-inch from end to end with the jaws closed and weighs 39.1 pounds.

Its bolt-in mounting base further ensures a firm set. Besides, the sturdy stainless steel spindle withstands a higher compression pressure. So, you can press the more substantial pieces safely.

It has two jaws – a right movable jaw expands 6.5” wide and 2.5” deep. The jaws are grove for a better grip on the project materials.

The 3600 swivel base enhances the function of this device even on restricted and recessed positions. The handles have oiled rubber washers that help prevent unwarranted sliding when working.

Specifications

- Jaw width: 6.5”

- Cast pipe jaws

- Swivel base: 360°

- Large anvil worktop

- Covered main screw

- Weight: 39.1 pounds

- Four bolt mounting tabs

Pros

- Steel U channels, Dual locks

- Bolt up mounting for stability

- Serrated clamp prevents slipping

- Heavy-duty screws for a firm grip

- Universal swivel for greater versatility

- Stainless steel spindles for greater pressure

- Hard diamond cut and grooved machined jaws

Cons

- weak rubber washer

Our Verdict

After researching and ranking the top ten performing vises, we selected Yoast Vises 465 as the top choice that your money can buy.

The vise offers advanced cutting and aligning capabilities due to the swivel base. Instead of manipulating the work piece, you simply rotate the base to get your desired clamp position.

The wide opening jaws allow you to perfectly nip a large piece with ease. Further, the serrated teeth offer additional firmness.

Though it’s expensive, you get a good value for money with this futuristic product. Undoubtedly, you should try it to experience its superb and flawless power.

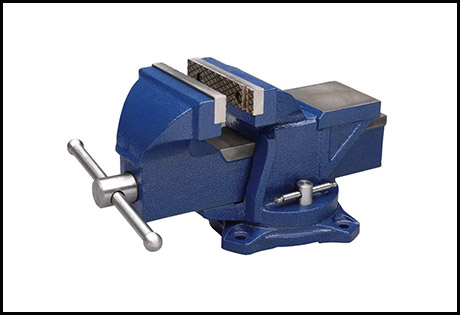

02 TEKTON 54004 4 Inch Swivel (Budget Choice)

The aggressive all-purpose TEKTON 4-Inch Swivel Bench Vise is a competitively priced bench top. For this reason and the reasonable pricing under $100, the vise has been on our list.

But you shouldn’t equate its low price with substandard features. Far from that, it has very advanced components usually available in the more expensive brands.

The first element is its grey high tensile die cast iron vise that is so strong to withstand 20,000 PSI. It can securely lock most types of steel to fasten, grid, cut, bend and sharpen without any risk of slippage.

The vise has a 1200 swivel base that hastens the work process. It harnesses the strength of a T-bar spindle to press the plane into a fastened position securely.

The main characteristics of this benchtop vise are the two jaws. Unlike those of an under-mount vise, one jaw is movable and the other fixed. The opening of 3” allows this device to grip most medium-duty sheets. The serrated clamps feature stainless steel braces and are replaceable.

The deep throat of 2.25” also supports all radial locks. Another advantage you get from this vise is a thick anvil plate measuring 2.625” x 2.625” inches.

It’s heavy enough to support all medium-duty tasks. It measures 15 pounds and is securely fitted to the base using three-bolt in screws size 0.375”. It measures 10.8 x 5 x 5.6 inches.

Specifications

- Bolt base: 3

- Swivel system: 120°

- Medium anvil size: 2.625 x 2.625

- Medium acme threaded screw

- Jaw size: 4”,

- Weight: 15 pounds

Pros

- Heavy-duty construction with reinforced cast iron

- Multi-functional gadget

- Anvil for safer hammering

- Faster adjustment

- Durable stainless steel T bar for better grip

- Secure three bolt fastening mechanism for more stability

- All-purpose duty

Cons

- Partial radial movement (only 120°)

- Not smoothly finished

Our Verdict

This is the ultimate choice for anyone looking to own a mini bench vise but expects a consistently reliable service from it.

You derived great savings from this cheaply priced product. So, if you want to start your DIY journey, you have a good reason to select this vise.

It’s easy to set up, needing just bolting on the worktop. Further, it’s light in weight and features acme drilled screws for a tighter clamp.

Its main drawback is the restrictive rotation span of its swivel. Additionally, it can only perform light and medium duties. We voted it in due to reasonable pricing as well as its robust performance.

03 Yost LV-4 Home Vise 4-1/2-inch (For Home Shops)

We voted for the handy Yost LV-4 Home Vise as the top choice for the garage work category. Its robust construction and small size make light all the wood and metal works, including gunsmith jobs.

It’s also makes plumbing tasks great fun with the reasonable pipe jaws of 0.6 to 1.85” diameter. Further, you are sure of secure support since the vise has a sturdy a four-hole 3/8” bolt mounting base.

The vise – made from a cast iron frame finished in powder coated blue color for long life and protection against rust. The heavy-frame augments the jaws function of this gripping device.

The jaws themselves feature a stainless steel serrated cladding bolted firmly into the main jaw material with high tensile steel screws. The jaws feature a wide, thick frame 4.5”. These great teeth open to capture wide 3-inch materials as well as a vertical grip of tasks up to 2.375”. Hence assures you of dependable completion of all tasks.

The molding and shaping function is improved by the massive 2.6 x 2.6-inch size anvil plate. Like most jaws, one part is movable for insert and release the clamp while the other is stationary.

Its spindle and center screws compress tough stainless steel materials. The base spins up to 2400 allowing for quick and fast manipulation of even the craziest cuts.

Specifications

- Jaw width: 4.5”

- Jaw opening: 3”

- Piping dimensions: 0.6 to 1.85”.

- Material: Cast iron

- 4-hole bolt in the base

- Swivel capacity: 240°

- Rustproof powder coating

Pros

- Sturdy build

- Rust-proof powder coating

- Compact base for non-slip projects

- Lightweight

- Strong steel jaws

Cons

- Mounting bolts sold separately

Our Verdict

This product is the cheapest of all the products we tested. It possesses superb quality functionalities that make it instant preferences for most DIY enthusiasts. It has a circular 2400 rotational capacity, and a great construction model applies the cast-iron technology.

Further, the locking mechanism simplifies most of its tasks and allows for better precision performance. It also has powerful jaws to grip your work. However, it’s meant for light-duty tasks around your home. But you don’t expect it to tackle strong and heavy materials.

Because of the above features, we vouch for this cheap yet feature-rich device to reliably perform all your light to medium duty home machining assignments rather than professional heavy-duty applications.

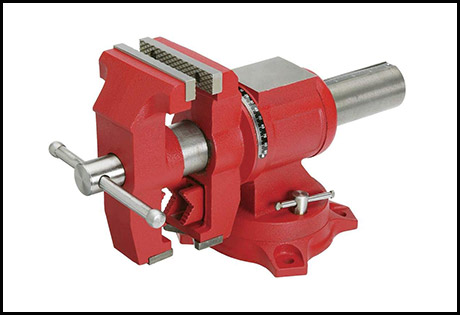

04 Yost 750-DI 5-inch Multi-Jaw Rotating Combination Pipe (For Professionals)

Yet another Yost Vises 750-DI Heavy Duty Multi-Jaw Rotating Combination and Bench makes this a great choice any machining professional would admire. And rightly so since it makes it to the top of the vises professional choose.

The reasons are many. Its heavy-duty ductile iron frame is two times stronger than other conventional iron materials and can withstand a higher tensile strength (60,000 PSI).

The deep-throated 4-inch jaw opening allows for a quick and better radical grab of any project material. The jaw opens an impressive 5-inch jaw wide, helping you to fasten any thick plates you may come across for manipulation.

It braced with a strong 4-bolt in mounting mechanism for stability. Its swivel spins universally for ease work. But when you need to set a position, simply engage one of the 12 locks to secure your project in place.

Piping work is made easy with self-aligned piping jaws that allow the right grip for pipe sizes from 0.125” to 3.5”. The vise jaws are secured by a 5” wide hardened steel serrated jaws assuring you of a perfect grip of any metal under its grasp.

With the reinforcement, the vise easily withstands a mighty 9,000 PSI clamping pressure. The hardened steel pins effectively relay a high pressure for the locking mechanism.

Bigger and stronger bolts ensure that the different components making up this versatile vise are completely fused together.

Specifications

- Swivel capacity: 360°

- Quick release pull out pin

- Iron material: Heavy-duty ductile

- Removable hardened steel jaws

- Vise head: 12 different lock positions

Pros

- Super strong ductile iron construction

- Compact and stable base for non-slip projects

- Universal rotation capability

- The heavyweight – 63 pounds – provides more stability

- Secure four bolt mounting mechanism

- Multi-functional jaws for pipes, beds, and clamps

Cons

- Mounting bolts sold separately

Our Verdict

The benefits that you gain from Yoast 750-DI are many. From the heavy weight of 63 impressive pounds to the multiple functions, allows you to complete your most demanding metal work on time and effortlessly.

The sturdy foundation allows it to tackle the heaviest of the project sheets. The 3600 swiveling base is ideal for quicker adjustments.

But it’s the jaws that make this particular vise a killer. It can bend sheets, grab pipes and twist V shapes. And your professionalism is enhanced by the 12 slots locking mechanism, ensuring that your projects’ dimensions are precise.

The setting, shifting, and adjusting pieces is easy. The robust 3600 rotating base helps you attain your desires without breaking a sweat.

It’s highly-priced, but with all these advanced functions, supported by a lifetime warranty, you get the value you expect from this professional gadget.

05 Grizzly G7062 5 Inch (For Multipurpose Operation)

If you are looking for a multipurpose vise that can undertake unlimited types of projects, then look no further than Grizzly G7062.

It features a powerful 5 inch (125mm) built-in pip jaw that rotates 3600 for any form of workpiece positioning.

The vise stands on a firm base riveted with a 4-hole bolt-in mounting to ensure maximum stability. Although it doesn’t come with the nuts, 0.5” inch bolts fit the bores well; hence you can use any hardened lugs for this purpose.

Further, you can use it for many applications. The circular construction makes shifting of the work parts between different positions on the vise a breeze.

The hardened stainless steel spindle ensures your grip function is firm yet malleable for the most intricate maneuvers. Better still, thumping has never been more straightforward on this robust product. It has a hard anvil to support all your hammering functions without destabilizing the worktop.

The wide-mouthed jaws comprise a gritted bracing for a firmer clamp of the project materials. What’s more, there is a ready tape along the vise to take an accurate measure while working – no need for interruptions to look for a measuring device.

It has a pipe clamp to grip circular pipes up to 3 inches.

Its 9 x 18 x 9 inches compact design can fit anywhere within the small confines of your tiny workshop. It weighs 42 pounds and its powder coat protects it from adverse weather conditions, ensuring long, stress-free service.

Specifications

- Weight: 42 pounds

- Color: Red

- Material: Cast iron

- Anvil: Heavy-duty

- Mounting systems: Four (bolt in)

- Spindle: Stainless steel

Pros

- Rotating jaw to simplify massive projects

- 360° swivel option for easy maneuvering

- Stainless steel handles and spindle for a higher strength

- 4-inch jaw captures large parts

Cons

- Only available in the US

- No mounting bolts

Our Verdict

The smooth circular and robust construction make the brand attractive. It’s designed to last through years of heavy and punishing projects.

You can convert intricate tasks to pleasant pastime with the help of a swivel that rotates as you work. With big jaw teeth, you stop worrying about the thickness of your project.

It’s also versatile. It takes both pipe and sheets with ease. And the convenient location of the pipe jaws beneath the primary jaws makes it work better. This setup allows you to undertake a synchronized project when you perform tasks that require both these two components concurrently.

From the above gains, we found that this quality product for sale possesses advanced features found only in the superior brands.

06 Wilton 11104

When you want to work conveniently and efficiently, the powered Wilton 11104 is the tool for you. Its most significant advantage is the electrical power supply. You don’t need your muscle to perform even the more demanding tasks. Just power it on and get your work accomplished.

The bright blue angular construction provides the toughness this bench vise requires to perform difficult chores. The solid metal cast improves its toughness.

The stable base has a sturdy swiveling gear with a rotation of 1800. This characteristic allows you to make intricate incisions and grabs that are not possible with fixed support.

The three holes 3/8” lug nuts in mounting mechanism support the vise in place, and the double lock swivel base ensures you can lock your preferred working angle.

Our research has established that hammering is a prominent part of metal work. The Wilton vise has a large anvil that effectively withstands your hammer pounds. It thus cushions the vise’s base and the worktop for denting and weakening due to constant bangs.

Though it doesn’t fall into Wilton’s Machinists 400 N category, its jaws are large enough to capture any project piece 4 inch wide. Our tests also confirmed that the powered jaws perform a stronger and more accurate grip.

Besides, the power assistance helps enhance the speed with which you can manipulate your project pieces. This benefit is more apparent when undertaking monotonous tasks. You also gain greater efficiency when working on many parts that require similar patterns and sizes.

Specifications

- Swivel: 180°

- Heavy padded square anvil

- Double lock for safety

- Spindle: stainless steel

- Weight: 15 pounds

- Jaw size: 4 inches

- Powered by: 120v electric power

Pros

- Bolt-in mounting

- Easy to install

- Power assistance for better functions

- Tough and solid metal cast construction

- Lifetime manufacturer’s warranty

Cons

- No lug bolts for mounting

Our Verdict

Whether you are an avid DIY enthusiast with constant projects or a small contractor with light metal works projects, the Wilton 11104 helps you turn your projects dreams into reality.

You enjoy the power assistance for faster tasks completion. Like Wilton’s heavy-duty C0, C1, C2, C3, and Hitch models this mode’s solid-state construction material supports your heavy pieces well. Further, the lifetime warranty props this specific make to our list.

The reinforced stainless spindles allow you to set strong pieces effortlessly. You also have the opportunity to hammer and resize your pieces thanks to the large and heavy anvil pad. This tool also provides the best value for its price.

07 Eclipse Quick Release

When you need a perfect project finish, and speed is of an essence, then the Eclipse Quick Release Woodworking Vise is worth your serious consideration. It’s made from cast iron to enhance stability.

The quick release function allows you to dislodge the pieces you are working in one move instead of repeated spinning of the spindle. This feature makes adjusting and changing whatever projects you are performing convenient.

To enhance safety, the vise incorporates a fused tommy bar that bends when you reach the maximum stretching point of the clamp. What this component does is to forewarn you that you have exceeded the maximum thresh hold. That protects your spindle from cracking under pressure.

It has two powerful jaws reinforced with serrated braces to clamp any hard piece securely. This sturdy grip simplifies all tough tasks. Further, they have a wide 9” jaw gap that allows you to secure a very thick work plate safely.

What we found interesting in this tool is the adjustable front dog that offers double functions on either a regular vise or tail vise. The dual options work well, especially when manipulating a large piece in a confined space.

We found that the cast iron construction provides stability and the heavyweight needed to endure the intense pressure and the constant thumping during milling.

Lastly, the vise features a good and sturdy design and is evenly spread out. It measures 20.1 x 12.1 x 9.1 inches, providing an ideal space to wiggle in. It’s designed to let your hands and workpiece move flawlessly around it.

Specifications

- Jaw: 9”

- Front stop (dog)

- Weight: 34.2 pounds

- Material gray cast iron

- Front stop: Adjustable

- Torque: 15Nm/132 PSI

Pros

- Full 9” jaw allows for wider garbs

- Tough brace for more firm grips

- Adjustable front vise for better maneuver

- Durable construction supports heavy-duty tasks

- Bolt-in mounting mechanism prevents uneven cuts and vibrations

- Powder coat for added protection

Cons

- Designed for woodworks only

Our Verdict

The Drillly team noted that its quick release feature made it stand out from its competitors. This mechanism hastens the pace at which you change and adjust your workpieces.

The vise is toughly constructed to offer added torque that you require to press thick plates. Further, the 12 inches wide jaws allow you to take in even the substantial thickness of 9”.

Its another unique feature is the front stopper (dog). The jaws have stoppers that allow you to set the grip at a position that offers maximum convenience during your woodworking. This feature helps you perform difficult maneuvers.

Overall, it has some functions not generally found in similar vises. However, even with these useful add-ons, it’s still reasonably priced and you get good value for the money you spend on it.

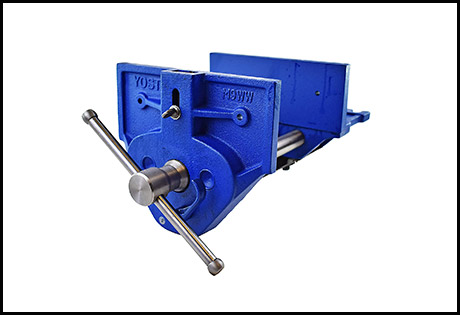

08 Yost M9WW Rapid Acting

Our team’s extensive bench vise reviews have established that the bright blue Yost M9WW is a top rated American made product, specifically designed to tackle all your woodworking requirements effortlessly.

It beams with many benefits. The most prominent is the heavy duty cast iron construction that makes it’s tough on all its work. Again the wide jaws are also beneficial for your work. It allows you to capture even the widest wood part without any worries,

These jaws are made from cast iron and reinforced with serrated stainless steel teeth. The teeth can be removed to widen the jaw width further. These teeth facilitate firm clamping without leaving marks on the workpiece.

The inclusion of the ingenious Yoast Rapid Action Nut is another benefit that makes this indispensable. The nut action allows you to open and close the vise instantly. It’s manipulated by the use of the central screw that allows the nut to engage and disengage.

The pre-drilled setting holes allow you to fix the vise on a worktop securely. The spacings are well laid to offer maximum stability.

You note that the jaws are dependent on the central screw for adjustments and clamping functions. This brand has reinforced screw threads to clamp firmly and move on the dies more smoothly. This buttress helps the jaws to grip on the workpiece securely.

Finally, as a standard benefit to all Yost vises, the M9WW comes with a lifetime warranty on manufacturing defects. This warranty covers all your doubts and anxiety on its performance. As a result, what you will enjoy is many years of trouble-free operations.

Specifications

- Weight: 32.1

- Color: blue

- Jaw width: 9”

- Rapid Action Nut

- Bolt-in mounting

- Cast iron construction

- Throat depth 3”

- Torque 30,000 PSI

Pros

- End stopper to prevent the central screw from falling out

- Buttressed main screws for smoother movements and firm grip

- Rapid release nut for quick operation

- Bench dog for grabbing oversized parts

- Tough built to withstand high pressure

Cons

- Mounting bolts not included

Our Verdict

Yost M9WW offers you the means to produce high-quality wood products without a struggle. You don’t need much training toinstall the USA made vice and work with it. The robust construction and simple design make it a simple gadget.

Even with the simplistic design, it’s still designed for durability and performance. Its wide jaws, the tough central screws and the rapid action nuts turn your every task into swift action.

What’s more, the vise is protected from quick deterioration by the powder coat. Besides, it’s guaranteed against unwarranted breakages and unreliable performance by the unlimited warranty cover.

These benefits make this a great device that deserves your attention.

09 Yost 750E 5 Inch

The heavy-duty, multipurpose Yost 750E is the bench vise for all your home improvement. It’s tough, compact and reliable.

You derive many benefits from this tool. You can shape, cut pipes and bend projects efficiently using the same instrument. The four bolt mounting system makes this devise a stable workhorse.

The swiveling base that rotates 3600 makes it easy to undertake all complex projects with ease. Another benefit of this robustly constructed product is its large anvil. Flattening pieces has never been more convenient from this device.

The powder coating allows it to operate even in extreme weather conditions. Besides, it’s a product supported by a world-class manufacturer. Hence, you enjoy the lifetime warranty offered by the makers.

What we found enticing about the vise is its multi-tasking ability. If you have plumbing issues, gun boring metal works or carpentry projects, you don’t need to look for different fasteners. Yost 750E tackles all these needs quickly and conveniently.

You further gain by having to finish all your various chores using just one vise. Its massive serrated jaws allow you to clamp pieces up to 5” and pipes/tubes whose diameter is 3” and below.

Specifications

- Height: 9-inch

- Weight: 35.9 pounds

- Jaw width: 5”

- Jaw opening: 5”

- Pipe jaw: 3”

- Swivel head

- Color: blue

Pros

- Cast iron mainframe and stainless steel spindle

- Powder coating to fight humidity and harsh climate

- Four mounting holes

- Large built-in anvil for quicker shaping

- Lockdown to hold clamp head at any angle

- Lifetime warranty

Cons

- Jaws without a grated surface

Our Verdict

Yoast 750E is one of the many reliable bench vises made by Yoast. Its 3600 swivel makes it work exceptionally well. The solid bolt-in mounting style enhances the stability of this device – effectively muffling the rattling and the wobbling associated with a weak platform.

The lockdown hold mechanism present in this tool enhances accuracy when working with precise dimensions. The many features let this product resolve all your home and DIY projects.

The fully rotating swivel simplifies your work while the reinforced steel spindle allows you to exert greater force. In summary, our rigid tests confirm that Yoast 750E is the top product in its category.

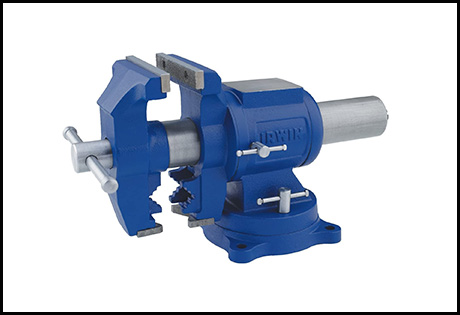

10 IRWIN Tools (4935505) Multi-Purpose

Our team included the IRWIN 4935505 in this list because of its sheer functionalities. Its huge benefits come from its versatility in handling multiple complicated tasks.

Its ability to undertake these assignments emanates from its durable cast iron construction. When it comes to its jaws, we noted that the large and sturdy 5” stationary and removable clamps hold most project widths firmly with ease.

Another reason for its superb performance is it’s the design. This particular model blends angular shapes with circular curves. The removable section of the jaw is angular for precise setting to the fixed part.

The anvil adds to the many conveniences, this vise provides. You perform your plating and flatting functions on the spot. Again, the anvil protects the worktop surface or the table top from the direct impact of these actions.

The tube jaws are the central feature of this device. These grips do rotate, making it easy to secure a tubular piece in any direction. This feature makes bending and twisting pipes very handy. It’s particularly helpful when working with long pipes within constrained confines.

The handle and lockdown clamps are stainless steel materials. We tested these materials and confirmed that these components are highly durable. They withstand high pressure as they secure heavy gauge pieces used by both carpenters and metalworkers.

Indeed, you need such strengths for tough jobs. To back the quality craftsmanship backed by modern technology that the device exhibits, the company offers a lifetime warranty on the manufacturing defect. This reassurance makes the workbench vise attractive to many users.

Specifications

- Swivel 360°

- Rotating pipe jaws

- Color: blue

- Jaw: 5”

- Four-hole bolt-in mounting with 3/8” nuts and bolts

- Weight: 33.1 pounds

Pros

- Convenient adjustment with fused steel handles

- Faster piece manipulation with base plate swivel

- Higher stability from bolt-in mounting

- Spindles made from fused steel materials

- Bright blue powder coating for high durability

- Heavy-duty cast iron construction for greater strength

Cons

- Designed for light-to medium-duty tasks

Our Verdict

When you want a high-performance vise for medium and light duties, IRWIN 4935505 aptly fits the bill. It has a flexible pipe jaw that hastens your tubing assignments.

The closely coupling primary jaws – with their wide 5” grab width makes in quite handy. Another reason upping its ranking is its weight. This is heavy enough to withstand the demanding light and medium duties that it’s designed to perform.

Best Bench Vise Buying Guide: Things to Look For

1. Jaws

These are the components that grip the wood or metal object during such manipulation. There are metal or wooden jaws. In case they are metallic but are designed mostly for woodwork, these jaws usually have a wooden bracing to help you avoid marring the workpiece.

The wood facing of a jaw is called a cheek. Most movable jaws have flexible dogs that brace the work against the stationary bench dog located flush to the work surface. You should consider the jaw size and style when looking for a good vise. I found flat jaws to be more versatile than others.

2. Swivel base

Most bench vises have rotating bases. These features allow for the planning of circular or angular cuts of the project materials. The bottom, therefore, is spiraled on a rotational gear that swivels horizontally or diagonally to deliver more complex patterns. Further, swiveling allows for easy access to the concave areas of the work.

3. Mounting

There are two mounting mechanisms on this tool. The bolt-on type features three or four bolts securing the bench top to the worktop. Bolting allows the device to withstand higher pressure and heavy load.

The clamp mounting system, on the other hand, is easier to set up. It is usually preferred when you desire to work temporarily at a location before removing the vise to another spot. Clamps work well where the workload is low. However, this mounting method doesn’t provide the required security.

4. Anvil

Sometimes, you need to hammer and straighten your project material. Hitting the worktop directly could damage the bracket clamps as well as the surface. Therefore, an anvil is necessary. An anvil is a flat metal top layered on top of the vise to withstand the impact of the hammer hits.

5. Quick Release

A screw is required to attach a clamp to the work material. Once the job is complete; you need to unfasten the latch. A quick-release mechanism allows for an instant release of the spindle instead of manual twisting of the vise all the way after completing the job. But not all models have this feature.

6. Griping Power

Gripping power refers to how securely the clamps hold a project piece. It is essential for high precision carving and cutting of the workpiece. The larger the clamp mouth; the better the grip. A clamp mouth refers to the throat of the clamp from the top to the base that also influences the width and breadth of a piece it can securely grab.

Others have grated/non-slip clamp tethered markings to secure the project materials against wobbling and sliding, even under intense pressure.

7. Price-to-Quality Ratio

When selecting your preferred device, you need to assess the price to quality ratio. A higher ration denotes a better task handling from the bench vise.

Typically, a more expensive product may come with quality material or additional features. However, this is not usually the case at all times. If your job is not particularly detailed, you may overlook some advanced features.

Work environments that involve high humidity may invite the uses of outdoor bench vises with powder coating that helps prevent rusting. It’s not that old vises are that bad.

If properly maintained they are as good as the new ones. You can check the craigslist or Black Friday discounts for getting quality models at a cheaper price.

Understanding the Bench Vise & Its Types

A vise is a mechanical apparatus that holds a segment of the workpiece tightly in place. It’s used mostly in metal works and woodworking.

It functions like extra strong and sturdy hands holding a workpiece. These devices also possess two clamps to help set the workpiece firmly in place. Many of these devices are attached to a bench, hence the term bench vise came into being.

These devices came into existence in many workshops before 1750. Clamping was done using a hammer and wedge. However, securely holding the workpiece was hard since the tool could only move radially.

In 1750, the introduction to a moveable horizontal jaw of the vise revolutionized the device. Then, anyone who needed to hold a workpiece manipulated the movable half of the vise horizontal adjustment. The preferred construction material was die-cast iron.

However, with the numerous pores left after the metal settles, the vise didn’t have much tensile to withstand high compression. In 1830, the invention of manufacturing techniques using robust forged steel changed all these.

The steel bench vise transformed the functions of a fastener with sturdy and compact materials that have enabled vise to manipulate increasingly tougher and heavier elements. This design and construction are considered the linchpin of the modern-day bench vise.

There are several types of vice for a workbench. A front vise enables you to clamp a workpiece at the edge of a workbench using two popping jaws on either side of the fastener. It also grips large parts utilizing the functions of a deadman as well as gripping elements on top of the workbench via a bench dog. These prevent the twisting of the workpiece when you use only one clamp to hold your work plane.

An end vise is another type that usually sits on the right-hand edge of a workbench and uses one central screw set to the corners of the bench top. It has a flexible jaw featuring multiple bench dog holes at the top aligned to the front row of dog holes on the workbench. Try using Roubo workbench for better results. Folding workbenches might cause a problem if not fitted properly.

The front and the end are similar since they both have a screw and two rods. These features allow you to set your work either horizontally if you want to plan a board, or upright when you want to place dovetails along a workpiece edge. But the front type offers more versatility in terms of gripping.

Broadly, two types of bench vises exist – the woodworking and the engineering types. The former is designed for wood pieces. Hence, it’s specially designed to clamp the timber workpiece using jaws that are encased with wood. This trait prevents clamp marks from showing off on the workpieces.

The engineering type is mainly designed for metal works. It’s heavy enough to support the massive steel workpieces firmly. Further, it features a flat metal jaw designed to grip metal objects.

What to Do with a Bench Vise?

The bench or tabletop vises are versatile tools. They perform many functions, such as undertaking cutting, drilling, sanding or gluing.

A vise helps you to cut through or along the edges of work materials fast and precisely. Since the clamps secure the workpiece firmly, there is no worry about wobbling or uneven cuts. Besides, it frees both your hands, so you work more quickly. Different uses of vices are stated below.

- Drilling a narrow hole through a thick board needs greater precision. Both the piece and the device have to be stable to produce a perfect drill. With such a tool and a table, you can drill to your specific measurements.

- Sanding is usually slow and boring. Besides, it produces much dust that hinders your proper assessment of the surface. This is why you need a bench vise to enhance the stability of the worktop. A firm surface allows you to apply more pressure finishing your work much faster and smoother.

- Gluing may be very messy if you smear incorrectly. And when the surface is uneven, it could spread to all unwanted locations. A quality product eliminates all these risks and allows you to apply glue at precisely when you intend. Further, it facilitates a faster and better drying of the adhesive.

How Does a Bench Vise Work?

A bench vise features clamps on both or one side adjustable with a screw to set a project in position. They have toggles to place the workpiece upright or horizontally, depending on which side you plan to work on.

These can utilize the edge or center of a workbench. Besides, they are flexible to specific positions. These features make work easier since they enable you to hold a piece at the required height, location, and grip. Further, they allow you to use both hands freely.

As such, vices help you to ensure better drilling operation, cut precisely, and sand more evenly. They vary in sizes and capacities; therefore, you can capture a small precision or electronic tool snugly in position during repairs or construction.

How to Install This Device?

Since holding parts is all a bench vise does, even if it’s a vintage model, it needs to be installed/mounted securely. Before you undertake the task, I would like you to get familiar with the machine thoroughly. You can fix them using any of the two methods.

Use a suitable attachment to clamp the vise to a worktop. These clamps have a top-to-bottom extension that can be affixed to the edge of the work surface easily and quickly.

The most stable installing method is to fit the tool on top of a worktop. You secure it with the bolt-in mounting so that it’s permanently fixed at the location.

There are a few unique techniques to fasten. You can use the vise supported on stands of optional base plates. These add-ons offer more accuracy when you are working on detailed jobs that need greater attention.

Try to maintain a good position as it’s critical. Remember that the higher the vise; the better the production.

The latter method offers the necessary safety against working with heavy and sharp parts. The earlier way is convenient for light and small parts. You also enjoy shifts in positions as you work with a clamped devise.

But we recommend that bolt-in mounting method to improve the vise elevation to the surface while at the same time avoid accidents.

Bench Vise Safety Tips

You understand how risky it could be working with machine tools. Bench vises are no different. You could suffer a severe injury and even loss a limb if you throw caution out of the window. You, therefore, must exercise extreme care every time you are using this machine or any other product for that matter. Adhering to such precautions help you enjoy a long working relationship with your fastener.

- Use the right components: Don’t use any part of the vises for a different task. For example, don’t use a pipe grab to lock a metallic sheet. Further, don’t hammer a piece while clamped on a jaw. Use an anvil harness instead. This measure helps improve the stability and efficiency of the tool.

- Use the right equipment for the job: There are many brands and each has its essential functions. Use the right vise for the right job. This saves time and improves efficiency.

- Wear ideal clothing: Safety outfit is important. You need to protect your ears, eyes, hands and even body against drops, freckles, and blasts. We urge you to use the correct size of goggles, gloves, earmuffs and industrial shoes. You should also wear tight-fitting and comfortable cloth while working with bench vises.

The stability of the vise for the workbench is everything. Therefore, set it firmly in place on top of a sturdy worktop that is supported by a firm foundation. Besides, test if for firmness before you start using it. In case it’s loose at the base, you risk minor inconveniences such as vibrations to significant accidents such as ripping the device out of the harness.

Bench vises Care & Maintenance

Unless you are not looking for an antique vise to keep in your collection, you need to take great care of your device. When you do that, you naturally derive greater value and joy when using this handy tool. You should develop a maintenance schedule to keep the device at a tip-top condition. Below are some of the factors you can keep in mind while caring for your beloved workhorse.

- Always clean the machine prior to use: During work, the workplace becomes messy with the bits and scraps from the machining. Some of these particles and residues could get stuck in the delicate segments of the machine, leading to damage as a result. Hence, wipe the tool and workplace to prevent such incidents.

- Inspection: Make a periodic inspection of the table vise as you deem suitable. In case you want to perform an extended and intricate job, it’s wise that you check each element of the tool to ensure that it’s correctly aligned and adequately fastened.

- Lubricate your bench vise: Cleaning and oiling your bench vise goes hand in hand. After wiping your machine, you also need to lubricate certain parts. Ensure that the moveable elements are well oiled and greased. Also, test the entire system for stability by refastening all screws and bolts of your old vise again.

- Protect against weather conditions: When your machine is not in use, cover it to prevent the buildup of dust and dirt. If you have a portable model, you can remove it from the worktop and store it in a closed box. These measures help prolong their lifespan while preventing the tools from rusting in case of high humidity.

A Word from Drillly

Although products from reputed brands like Craftsman, Harbor Freight, Gressel, Record, Babco, Menards, Benchcrafted Tail Vise, Ridgid, Pony, Larin, Woodword Fab, Bessey, Veritas or Olympia didn’t make it to our shortlist, this does not mean they are of the lowest quality. Since we could afford only 10 choices here, this is the reason those vises ended up being off this review prepared by the Drillly team.

Vises come in many shapes and sizes. All these distinctions facilitate a wide range of functions while they also perform particular tasks, ranging from light duties to heavy professional craftsmanship.

A perfect bench vise has swivels. This function offers additional efficiency and delivers quality at a price that you can afford. So, apart from the price, check for jaw widths, jaw throat, mounting bolts as well as the construction materials. These components determine how well such a device will work.

Die-cast and stainless steel are favorable construction materials. They improve the lifespan of the vises. Regarding aesthetics, we discovered that circular body molds are smoother to work with although angular shapes provide more significant strengths. So, check for a blend with these shapes and have warranties.

To conclude, our experts suggest that you will derive better value for money if you start with small devices and grow as your aptitude and workload increases.