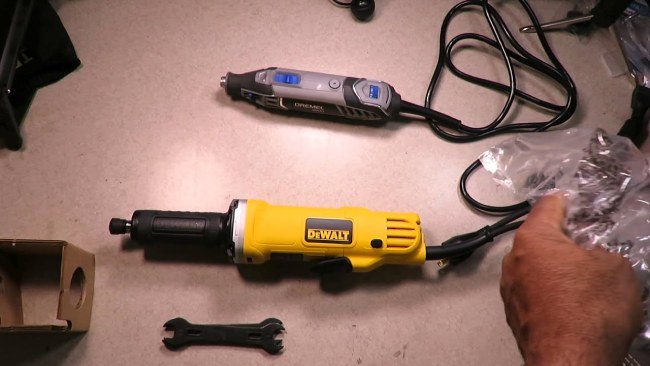

The differences between die grinders and rotary tools are subtle. Rotary tools like Dremels are lightweight, more convenient to use, and less powerful. They are perfect for intricate jobs.

On the other hand, die grinders are a bit bulky and produce a lot of torque essential for heavy-duty grinding/sanding. They are less portable and aren’t equipped for delicate projects.

What’s a die grinder?

Die grinders are heavy-duty power tools that can grind metal, wood, or plastic. These heavy-duty tools are used to polish large areas of metal, remove rust quickly, and smooth out surfaces. They provide speed and power in your curving/maintenance work.

Die grinders are a special type of rotary tool that contains a rotating spindle and a cutting bit attached by a collet. Rotary tools, in general, refer to tools that spin on an axis and can be equipped with different bits.

What are rotary tools?

Although all the Dremels are also rotary tools, not every rotary tool is considered a Dremel. It is primarily a brand name that manufactures a wide range of rotary tools. Over time, we have been familiarized with the name and started calling almost all rotary tools Dremels.

These compact and lightweight tools provide high RPM for more intricate and detailed works like sanding, grinding, scraping, polishing, drilling, routing, removing grout, cutting, etching, sharpening, cleaning, and engraving.

Die Grinder vs Rotary Tool: How They Differ

A quick look

| Feature | Die Grinder | Rotary tools |

| Powered by | Air, Electricity | Electricity |

| Size | Comparatively larger | Smaller |

| Torque count | Higher torque and material removal rate | Lower torque and material removal rate |

| Price | Cheap (Air) Expensive (chordless) |

More expensive |

| Speed | Lower RPM (20,000 to 25,000) | Higher RPM (5,000 to 35,000) |

| Precision | Less precise, optimum for heavy-duty tasks | More accurate, optimum for intricate tasks |

1. Size

Die Grinder

Die grinders are bulky and long. Even a compact model Die grinder is bigger than a rotary tool like Dremel. The enormous size and weight make it hard to work with Die grinders for a long time.

All the parts and components follow the same trend as well.

Usually, a rotary tool bit shank is about 1/16-? inches whereas on a die grinder it is 1/4”.

Rotary tools

Rotary tools were primarily designed to reach tough corners and perform detailed jobs. That’s why they are very comfortable to handle and compact in design. As a perk of being lightweight and nifty, they are perfect for intricate jobs.

Dremels offer portability and convenience where die grinders have raw grinding power.

2. Speed

Die Grinder

Despite providing enormous power to your curving, metalworking process, the heavier Die grinders, with their larger blades, run at a slower RPM than the rotary tools.

Even the most powerful Die grinder runs around 25,000 RPM, which is well within the effective range of most rotary tools. They focus on more torque, not RPM.

Rotary tools

Being lightweight and compact, it’s no surprise that the smaller motor of rotary tools also produces more RPM compared to Die grinders. Rotary tools need more speed for intricate and detailed jobs and that’s why they need more speed.

Tools like Dremels sacrifice their torque to gain tremendous rotational speed. Most Rotary tools can produce around 5,000-35,000 RPM.

3. Versatility

Die Grinder

Die grinders win this round. Despite being a heavy-duty champion, they come in various sizes and shapes. You’ll have little or no difficulty finding the perfect die grinder for your small to large tasks.

Rotary tools

Rotary tools are compact and designed for intricate work. It might be true that they’ll help you get into the tough-to-reach spots and angles, but they can’t do any of the heavy-duty jobs that a die grinder is specialized in.

4. Resilience

Die Grinder

Being bigger and more powerful than rotary tools, die grinders also feature more resilience. They produce more torque and are much more comfortable when you need extended use. Most are powered by air compressors that makes them more resilient to overheating.

Rotary tools

Rotary tools get heated up easily compared to die grinders. Like any other electronic device, Rotary tools like Dremel aren’t well-equipped for continuous use. The cordless ones are more prone to overheating than the regular ones.

Go through the user manual to get precise instructions on how you can safely use your Rotary tools.

5. Power

Die Grinder

Die grinders are mostly powered by air compressors, which means they are cooled by the continuous air supply from the compression. As a result, you can use the pneumatic die grinder for a long time without any discomfort. They also provide a higher material removal rate.

However, there are also electric tools if you have a thing for them. Cordless die grinders are becoming increasingly popular nowadays.

Rotary tools

Rotary tools only run on electricity, which increases their chance of overheating. Even some of the superior models feature only 1.8 amp whereas the standard Die grinders require 11 amps or higher.

Rotary tools are perfect for small crafts, DIY, and home improvement. On the flip side, die grinders are for heavy-duty tasks.

6. Price

Die Grinder

You can find a decent-quality die grinder for about $30-100. Since they run on air compressors, the maintenance cost is also close to none.

Rotary tools

These tools usually come in sets and are considerably more expensive than die grinders. You’ll need to spend around $70-120 to get your hand on a premium set.

Die Grinder vs Rotary Tool: Pros and Cons

Die Grinder

Pros

- More powerful (11 amps or higher)

- More torque

- Can cut through hard materials like thick metal

- Perfect for heavy-duty grinding

- Don’t get overheated quickly

- Come with a speed adjustment feature

- Easily affordable

Cons

- A little heavy and bulky

- Not good for precise works

- Slow spinning speed

- Require more power to run

Rotary tools

Pros

- Higher RPM count

- Consume less amount of power

- Compact and lightweight

- Perfect for intricate/detailed works

- Convenient to use

- Provide higher accuracy

Cons

- Get overheated with continuous use

- Not good for heavy-duty jobs

- Pricey

- Require electricity to run

Die grinder vs rotary tool: Which one to choose?

The perfect answer lies in your working environment. You should pick one best suited to your specific needs. Both die grinders and rotary tools work like a charm, but only in their designated work environments.

For example, if you have an air compressor available, go for a die grinder. If you need to carry your tools around, a cordless grinder is what you need. Die grinders are perfect for heavy-duty use when you’ll need a lot of torque and raw grinding power.

On the other hand, if you long for more precise works, a Rotary tool like Dremel will be perfect for you. The compact design and higher RPM will allow you to perform small to medium-sized tasks almost effortlessly.

If you are into works like carving wood/stone, working with glass, or making jewelry, Rotary tools are your best option.

FAQs

1. Is a rotary tool the same as a Dremel?

Ans: Not exactly. Dremel is a brand that manufactures and supplies rotary tools. Over time, the name has become both a brand and a product. Most people refer to rotary tools when they say the name. In a nutshell, all Dremels are rotary tools, but not all rotary tools are from Dremels. Some other companies that produce rotary tools are Milwaukee, Dewalt, and Ryobi.

2. Can Dremels cut metal?

Ans: Yes, of course. Most rotary tools like Dremels are designed to cut, groove, and trim all kinds of metal. By changing the bits, you’ll also be able to cut thin wood, ceramics, and plastics.