You may all know a band saw. But you may not realize that they come in different designs and shapes. Therefore, it is difficult to recognize the modern ones immediately. This is because they have transformed from the original form you know.

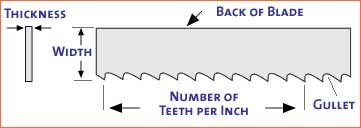

Whatever the size or configurations, a band saw blade is a continuous steel belt with a serrated edge. These tools are indispensable for any woodwork. As such, they are a prominent feature of most workshops.

When you understand how to measure bandsaw blade, you start your project on the right footing. Before you select the band saw, you need to realize that different tasks require blades with varying width and radii. You should check with the manufacturers on the sizes they recommend for different jobs. Generally, these blade edges have a regular, hooked or skipped pattern.

Understanding these grooves and appreciating their key functions will help you purchase the right blade for the right job. If you are unsure of the correct bandsaw blade configuration, then contact any accredited hardware store for further advises on your specific blade requirements.

Basics of Blade Measurements

Band saw are primarily used for cutting straight lines or circular arches. You may perform these cuts on either a wooden or a metal workpiece. The type of materials you opt to work on as well as the required cutting pattern(s) determine(s) the kind of band saw blade you have to select.

Now that you have identified your pending project, your next immediate question would be compelling – how to measure the bandsaw blade?

The blade widths range from 1/8” to ½.” The thinner the blade, the more acute curve it can makes. Hence a thick blade cuts a larger radial in comparison to a thin one.

A thinner blade is suitable for straight cuts on thin wood while a thicker edge makes work on the thick planks manageable. Further, a thin blade makes a perfectly thin incision without leaving a rough surface.

A thin blade of 1/8” makes a slim curve of 1/8”. If you pick a ½” wide blade, you can only curve 2-5/8” or more. It can’t make a cut less than this radius.

Most manufacturers present band saw blade length charts. These charts detail how to measure a bandsaw blade. They provide the maximum and minimum width of the blade for different jobs. The illustrations also provide for the maximum bend each blade width can make on either a wooden or metal workpiece.

How to Measure a Bandsaw Blade?

Determining the size of your preferred bandsaw blade is easy. You can get the right dimensions from your bandsaw machine. Besides, many popular bandsaw brand manufacturers keep a schedule of different sizes. Yet again, you can procure these lengths from the woodworking blog sites.

Unfortunately, you are still not out of the woods yet. Even when you have this information, a nagging question may still confront you – How do I measure band saw blade length? Taking an accurate measurement of your blade is sequential. You need a writing pad and pen to record your measures. Simply follow the steps below.

- Register a mark on the blade

- Use a measuring tape to make the starting point on a worktop or a large table surface

- Align the marked point of the blade to the marking on the surface.

- Roll the blade from the starting mark to the where the blade mark hits the surface next.

- Measure the length between the two spots – starting and the end –using the tape measure.

- Record the difference in these distance in the paper.

That’s it! Now, you have the actual blade length!

It’s important to know the basics of a bandsaw blade. Further, the different kinds of blades as well as are their respective applications can help you establish how to measure band saw blade.

Finally, follow the given steps above to get the correct blade length. But you also need to know that your bandsaw machine needs adequate oiling to function correctly. Using protective clothing helps prevent accidental rips, ensuring that you finish your project not only within time but also to a gleaming finish.

Different Types of Band Saw Blades and Ideal Measurements

As mentioned in the previous section of this write-up, bandsaw blades vary. We detail the five main categories of blade patterns. These patterns influence the cut per inch for each blade. The more the CPI, the smoother the cut surface, and vice versa.

1. Regular Blade

A regular serrated bandsaw blade is the most popular blade type. It features a deep gullet and straight-faced canines. The teeth here are regular 00 rakes with narrow, even spacing between them.

This kind of blade is useful for cutting materials of low width bands. It performs a perfect cutoff or contour sawing. It’s hence ideal for wood, metal and plastic pieces of thin widths. The teeth are closely gritted with no visible allowance between them.

2. Hook Blade

A hook-incised blade has a deep gullet and widely interspaced between each spike. The incision themselves are slated at about 100 rake angle.

This kind of blade is suitable for cutting materials of larger thickness. The main advantage is in its quick action and the ability to split thicker planks of wood and plastics.

If you envisage larger and longer cuts while bending the workpiece out of your way, then this blade is ideal for your project.

3. Skip Blade

Skip-serrated bandsaw blade has shallow gullets and widely gapped incisors. The 900 teeth, as well as the 00 rakes, are the standard bandsaw blade lengths of this blade.

When you are working with delicate materials that are susceptible to chipping and flaking, then this blade is an excellent cutter. Hence, it performs best for reshaping materials such as softwood, plastics, and non-ferrous metals. The extra-wide spacing facilitates this delicate cutting functions.

4. Wavy Toothed Blades

When your projects involve slicing thin sheet and tubes, then you would wonder – what band saw blade size do I need? Worry no more. You should look for the wavy-toothed bandsaw blade.

This kind of blade features rugged teeth that twist from left to right and back continually. Again, to enhance its functions, the gaps between the teeth are filed with raker teeth.

5. Variable Pitch Blade

This kind of blade is unique in its teeth configurations. Variable blade possesses differently patterned teeth. The teeth space and length variations allow it to make precise curricular incisions and joinery work and you will get a balanced saw performance.

When you want to work quickly and finish the project surface more smoothly, then you could opt for the variable pitch bandsaw blade.