A bandsaw comes with a sharp and long blade involving a steady band of serrated metal reached out between something like two wheels in order to cut different materials. These tools are used, of course with great cautions, for the most part in carpentry, metalworking, and lurching, yet can cut a combination of materials.

Band saws are basically a couple of wheels, or once in a while three wheels, holding a meagre pivoting blade, a table to help the work and an engine to run it. If you’ve the best band saw, you can use it to cut bends, even in thick timber, for example, in making cabriole legs, tearing amble, cross-cutting short pieces, and cutting sporadic shapes.

Primary Uses for a Bandsaw

What is a band saw used for you might ask. Well do not worry, we will answer that question. The primary uses of a band saw is resaw, to resaw implies that you cut the wooden board along its width. You can utilize it to reset the edge just as the essence of the board either to acknowledge the edge and face of the board originates from the factory.

You can reset its edges without anyone else’s input. Cutting veneer is another utilization of band saw although it can be performed with other cutting tools too. The facade is a slight cut of the wooden board, it builds the likelihood of various plans. You can make bowed cover by utilizing a band saw to make a bent piece of the furnishings. The band saw is a little factory used to process the little logs.

1. Sawing Something

Sawing is the way toward slicing vertically through the width of a board. Generally, it is cutting the board along the most troublesome measurement, regularly vertically through the whole length.

A model takes ¾-inch thick board and re-saw it with the goal that it is just ½-inch thick. This would include slicing through the whole length of the board to dispose of ¼-inch.

Sawing is a typical practice in carpentry, and a band saw is the ideal device to use for re-sawing. At whatever point you have wood that is unreasonably thick for your undertaking, re-sawing is the procedure you’ll experience to persuade the wood to be the right thickness.

2. Re-Cutting an Object (Wooden/Metal)

You can utilize this method when making a facade, which expects you to cut slender bits of wood. You can likewise utilize this procedure when making boxes that use ½-inch thick dividers from ¾-inch stock wood.

Re-sawing is a magnificent band saw use. As a carpenter, you’ll have to continually re-saw, and this is an incredible motivation to keep your band saw helpful.

3. Creating Veneer

A thicker veneer has the special ability that helps you investigate more plan and conceivable outcomes. You utilize veneer while putting a costly timber surface firmly on another compatible wooden base (as a rule of more affordable wood). One can likewise utilize veneer to attempt and complement the look of the wood grain.

In a request to think of an ideal veneer, you should saw a piece of wood board into slight pieces. The slight pieces would then be able to be utilized to frame a coordinated set of wood, similar to a lot of bent entryways or cabinet front countenances.

This band saw has the potentiality to enable you to improve a veneer than some other instrument. On the off chance that you lean toward more slender veneer, at that point, you basically change the particular band saw in order to make little cuts. These cuts may measure 3/64-inch to the minimum and make veneers with very low thickness.

If you’re making veneer, you’ll see it as an incredible use of the band saw.

4. Prepping Logs

A band saw may come in handy for a little plant. As it can work like an efficient log mill, one can utilize it to resize and shape small logs, similar to those that originate from your property.

This tool is an energizing and fun approach to invest your free energy and tidy up undesirable bits of tree branches and stems in your neighborhood and patio.

5. Preparing Bent Laminations

At the point when a task requires the wood to be bowed, for example, a round box, it is exceptionally hard to twist thick wood. Utilizing a band saw, you cut dainty material out of the thick wood. At that point, as you stick the slight bits of wood together, you twist them into the ideal shape.

Enable the paste to dry, and you’ll have utilized a band saw to make twisted surfaces out of thick wood. Making twisted laminations isn’t an apprentice carpentry assignment, yet sooner or later, you’ll most likely discover a task that requires it. The band saw is the ideal apparatus for the activity.

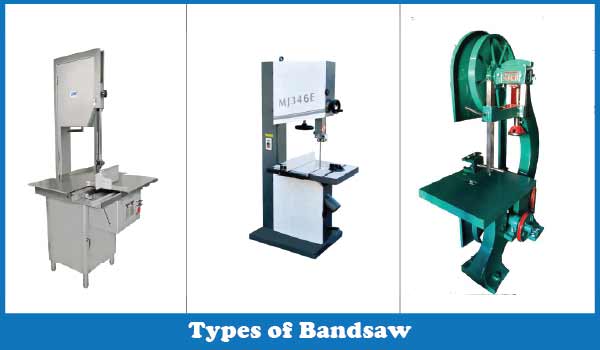

Types of Bandsaw & Their Uses

There are varieties of bandsaw and their unique uses. Choosing a bandsaw should be based on the kind of project you are doing, understanding what exactly you need the band saw for will help you in getting the perfect one.

1. Wood Bandsaw

A wood band saw is a well-known among beginners and expert carpenters. A wood band saw, if chosen the right one, can genuinely be an adaptable machine.

While littler stationary band saws are utilized in workshops, timber processes additionally work huge scale band saws for tearing wood. The band saw has the special capacity to work with timber that is of a bigger measurement, and in light of the fact that they have a little kerf, or cut size, there is less of the quality timber squandered.

Uses for Band Saw in Woodworking

These are some of the uses of band saw in woodworking, such as cutting curves, irregular shapes, creating cabriole legs, ripping lumber, and crosscutting short pieces.

2. Metal Band Saw

There are several distinctive band saw in the market today, a metal band saw can be said to be the perfect power device for the job that requires that you to go through intense metal. Band saws that are used for cutting metal by and large fall into two classifications, they are the vertical and the horizontal band saw.

Though they do require some additional support, this is not all the time, they also have some extra highlights implicit. A coolant is situated strategically that keeps the blades greased up and cool, an internal cooling system reduces the temperature of the drill presses and saws while drilling and cutting solid materials. The brush wheels brush off excess chippings keeping metal chips from getting stuck and accumulating in and on the blade. These features are normal to find on these sorts of band saws.

Uses of a Band Saw in Metalworking

Listed below are some of the uses of band saw in metal working, such as polishing and filing metal to fine tune the product, barring stocks to length and cut pipes, cutting metal stocks down to smaller and manageable sizes, and creating new blades with the right measurement for different band saws.

3. Vertical Band Saw

A vertical band saw is so adaptable it very well may be utilized to make sophisticated shapes and lines that different kinds of band saws cannot rival. Just as being skilled at cutting confounded shapes, the vertical band saw can likewise perform exactness cut straight lines, making it an incredible all-rounder power instrument.

These saws have a great slicing limit and the capacity to slice through materials quick, and with brush-wheels introduced they have wellbeing measures set up to guarantee chips don’t wind up stuck in its metal teeth.

Uses of a Vertical Band Saw

The uses of a vertical band saw are numerous, here are some of them.

- It is used for filing

- It is used for contour cutting

- It is used for polishing

4. Horizontal Band Saw

This tool has a place among the few more extensive classes of a band saw, appreciated by both beginner and expert craftsmen. These kinds of saws allow for different applications like paring longer and strong materials down, notwithstanding, not all that perfect for creating muddled shapes or bent lines.

A common horizontal band saw uses its toothed end by holding the target material steady and firm while the blades of this band swings down gradually through the cut. When the cutting is finished, the band saw will consequently kill with a change outing to evade potential wounds to the user as well as operator.

Uses of a Band Saw (Horizontal)

- It is used to cut the stock down to sizes

- It is used to cut metal stock to length

- It is used to cut the plastic stock to length

5. Meat band saw

The meat band saw is utilized for cutting and slicing different types of meat. They are commonly produced using tempered steel, and they are built so that cleaning them is never an issue, and this is so because of the touchy material they work with.

The meat band saws are usually a butcher’s closest companion, yet it is not just held for the experts. Numerous enthusiastic meat darlings have their own meat band saw at home to make the absolutely ideal cuts of steak and lamb.

Uses of a Meat Band Saw

- It is used for spouts or mincers for sausage

- It is used for cutting meat

- It is used for carving different meat shapes

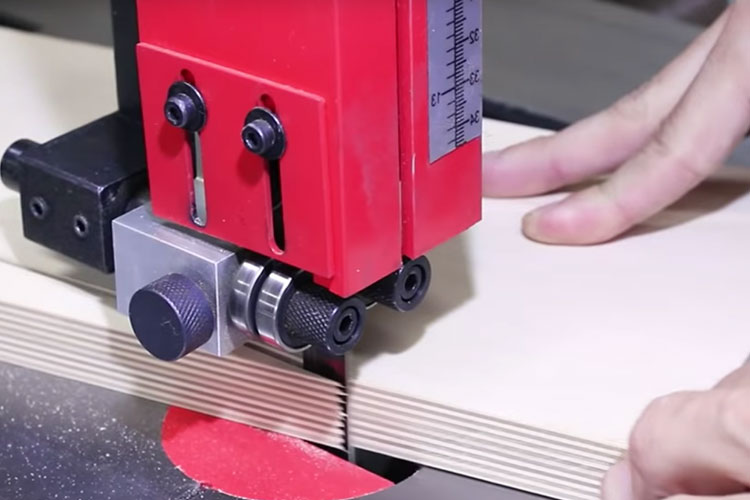

The band saw is an extraordinary and flexible item to work with. It can get you a few plans and shapes in the event that you can get the opportunity to move the machine in the manner in which that you need it. To begin with, you have to set-up the machine so it will be tough once the engine is turning. Spot the blade by securing it in the belt territory. Make a point to utilize legitimately honed blade with the goal that the yield is smooth.

For cutting straight edges, have a firm hold and enduring hand with the goal that the line will be straight. Leave additional material for the smoothing procedure. For the bends, give a few alleviations focuses with the goal that the way toward cutting the bend will be isolated into littler assignments.

At last, pursue appropriate wellbeing guidelines and practices while taking a shot at your venture.