If you work in the wood/metal industry or have a woodworking/metalworking shop, you most probably are familiar with the concept of drill press or milling machine. Both of them are versatile power tools that can help you to drill holes and make curves into a wooden/metal/composite plate.

However, drill presses aren’t the same as the milling machine. Whatever your drill machine can do, mills can do that and more. If you want to learn about the difference between those power tools in details, you’re in the right place. Let’s dive in.

Basics of Drill Press vs Mill

-

A quick look at a drill press?

A drill press is a stationary, upright, hand-operated drilling machine that moves along the z-axis to drill into hard materials. A rotating spindle holds the drill, and the workpiece is clamped in a vise on its table. You can pick various diameters for the holes by switching between different drill bits. It allows you to decide on how deep you want to plunge the hole and how much force you want to push down with. Besides, there’s an option you can use to cut out square holes with a certain kind of bit. Most of these machines also let you adjust the rotating speed of the drill.

Drill Press: Pros and cons

Pros

- Beginner-friendly

- Manageable assembly and easy to handle

- Effective functionality

- Sturdy structure with a solid steel column

- Great support at table and head

Cons

- Hard to switch positions

- Sluggish operation

-

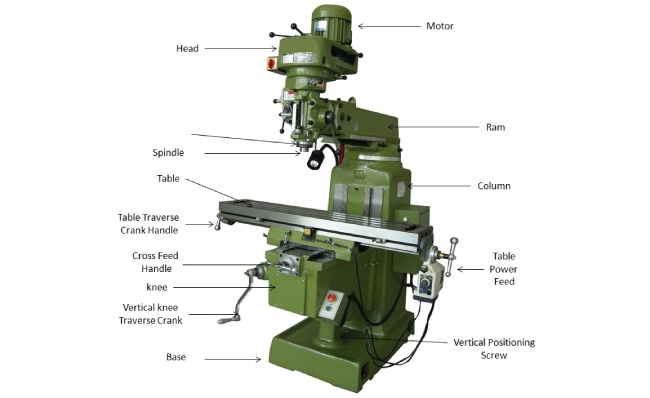

A quick look at a milling machine?

A milling machine is as well a stationary machine you’ll mostly see in workshops. These machines can perform different operations such as cutting, drilling, facing off, or putting in a pilot hole since various tools can be inserted into its spinning head. There are three different types of milling machines – horizontal, vertical, and universal milling machines. The table on most of these machines can move in all three (x,y,z) directions and offer three axes of cuts. Some allow the tool’s head to turn and rotate when you need. A special kind of revolving cutter called a milling cutter is used for removing metallic elements from workpieces. This cutter works on both flat or rough, irregular surfaces.

Mill: Pros and cons

Pros

- Versatile and feature-rich

- All 3-axes motion

- Great accuracy in the final products

- Convertable into a drill press

Cons

- Takes more workspace

- Complicated operation

- Rather pricey

Drill Press vs. Mill: How Do They Differ?

1. Ability to move

-

Drill Press

A drill press can only move up or down along with the z-axis while maintaining a straight line, so it fails to operate with multiple workpieces at the same time.

-

Mill

In contrast, a milling machine moves in 3 directions (x, y, and z-axis) and can be used to flatten the surface of a workpiece almost effortlessly. This process is often regarded as “facing-off”. A milling machine can cut pieces to a particular measurement and create slots into them.

-

Winner

Do we have a winner? The versatile milling machine seems to beat the fixed drill press when it comes to the flexibility to perform in all 3 axes of motion.

2. Size

-

Drill Press

The hand-operated drill press devices appear smaller in size and dimensions when compared to a standard milling machine. Some are designed to sit on top of the workbench and some relatively larger models stand on the floor.

-

Mill

Milling machines can’t be put on a tabletop, they’re set right up on the flooring of the workshop. They can be considerably large and take up a good amount of workspace due to the expandable machinery they operate with.

-

Winner

The drill press is way more compact in terms of overall dimensions. You’ll find both drill presses and milling machines in industrial variants which can be enormous, especially the milling machines.

3. Versatility

-

Drill Press

Drill presses are confined to a certain degree when it comes to their applications. The drill bit only moves along a particular axis and can’t be altered in most cases. The single significant purpose of this machine is to drill grooves and holes into the workpiece. you’ll need to hold your workpiece physically and move it around from side to side to get your drilling right. You may have to compromise the stability and precision in the process.

-

Mill

From drilling to cutting to facing-off, a milling machine got it all covered up. You can use a mill just like a drill press and get more facilities and flexibility out of it. A good way to exemplify this is to mention its axes of motion once more.

Drilling and boring workpieces in every possible direction and edging their sides at the same time perfectly define the level of versatility a milling machine has compared to a drill press.

-

Winner

The milling machine is way ahead of a drill press in terms of versatility and options for flexible working. The axes of motion and milling cutter always make a milling machine outdo a drill press.

4. Accuracy

-

Drill Press

A drill press is more of a rough-cut device. You may have to put in a great amount of heavy labor and time to make it work as a precise piece of machine. It’ll require you to go through countless repetitions and cycles over the same piece to get an ultimate finished product.

In a nutshell, the drill press may offer quite an acceptable result but is not anywhere near a mill.

-

Mill

With the precise and simultaneous movement in all the axes, you may rest assured that your final piece will come out nice and clean. Besides, you have the option to place your material in several positions and modify the results.

-

Winner

Milling machines once again seem to take the cake in terms of accuracy and exactness. You can set almost any pattern and cut it out effortlessly and accurately.

5. Price

-

Drill Press

You’ll get an average-size new drill press for roughly between $300 and $1000 depending on the brand, features, and place you order from.

-

Mill

A moderate-size new manual milling machine unit may cost you around a couple of thousand, roughly starting from $1000 and reaching up to $10,000. The commercial units will cost you way more because of the value they can bring in.

-

Winner

It’s hard to pick a winner here considering the amount of output you get from a milling machine. But it’s clear which one is less pricey – you can get a drill press and save a lot of cash.

How Do You Turn a Drill Press Into a Milling Machine?

1. Clamp up the material

Clamp up the material tight in a vise that’s usually on top of the two separate guides.

2. Isolate the X and Y direction

Next up, you’ll need to isolate both X, and Y directions of the axes of motion using the two separate guides.

3. Control the guides manually

Go ahead and use your hands to regulate the guides to transform the drill press into a custom milling device.

Note: You may find it super hard and your effort may not be completely worth it in the end, but you sure can give it a try in case you’re in a pinch.

When should you get a drill press?

Go for a drill press when you understand the nature of this machine and have low-impact woodworking to do for a DIY project. If you want a stationary drilling device in your workshop to drill holes into wood or PVC trim with slightly less precision and don’t want to use it professionally, a drill press would be your best bet. You can also save quite an amount.

When should you get a milling machine?

A milling machine is all that a drill press is and more. It’s a more appropriate choice if you are prepared to invest in the woodworking passion and have the necessary funding.

The milling press will have a lot of usefulness be it a professional workshop or a long-held hobby. It will help unleash your true creative potential with all those modifications and extra drill bits.

FAQs:

1. Can a mill be used as a drill press?

Ans: Yes, a mill can be used to drill holes just like a drill press. Besides, you’ll get more accurate results.

2. What is the best speed to mill aluminum?

Ans: 800-1500 SFM is the recommended best speed when you mill aluminum alloys.

3. Can you use a pillar drill as a mill?

Ans: Sure, you can! It’s possible to use a pillar drill like a mill, but it’ll take a fair bit of hard work and numerous repetitions that you might not feel worth doing. And it might never work so rigid as an actual mill. Only opt for it when in a pinch.