If you are planning to buy and use a scroll saw, you must focus on many important rules and guidelines. First of all, you should make a wise choice when buying this tool. Next, there are many scroll saw tips and techniques you must learn and stick to in order to get a satisfactory result. In addition, maintaining the machine will ensure prolonged service.

In this article, we will talk about the ways in which you can bring versatility to the operations of your machine. We strongly recommend you to go through the expert tips and tricks on all of these matters, especially if you are a new scroll saw user. These tips and advice will help you get the best out of your product. Let’s learn more about these amazing machines!

Scroll Saw Tips and Techniques: From Purchase to Maintenance

Stay with us to read the experts’ insights into the overall usability and experience with a scroll saw and some valuable advice to follow. We will provide some useful tips for the buyers, for the users, including different types of applications, as well as tips for safety and maintenance. Let’s begin.

Scroll Saw Tips for Buyers

There are many factors that matter when one wants to buy a scroll saw. Those include blade types, tensioning features, speed, table tilt, throat size, vibration, weight, etc. Let’s learn more about each of these features.

1. Blade types and tensioning features

Any standard scroll saw that modern buyers would choose to buy uses two kinds of blades, such as the pin-end plain-end blades. Pin-end blades are characterized by a pin, while the flat-end or plain-end blades require clamps to hold it in place. You should buy a flat-end blade, as the pin-end type is not suitable for sharp and detailed cuts.

2. Speed

Strokes per minute determine the speed. You should buy a saw that has at least two-speed options. Some models even have more options. You should not go for the single, fixed speed model. The variable speed machine will enable flexibility and more opportunities for work. You can also work with many different materials if you have a saw like that.

3. Table Tilt

If you want to be able to cut on an angle, you should pay attention to the table tilt. You should not get a saw that tilts one way. Of course, this is not relevant if you will not use it for angled cuts.

4. Throat Size

The throat is one of the essential parts of a scroll saw and its size is measured from the saw blade until the saw back. 16-inch throat size is the minimum you should go for. There are even some saws with a throat size measuring 30 inches. Majority of projects require up to 20 inches.

5. the Thickness of Cuts and Cutting Actions

The thickness of cut is the maximum value of cut you can achieve with a saw. Majority of saw models in the market provide a 2-inch cut thickness. The maximum you can easily find on the market measures 3¼4?.

6. Vibration

When buying your saw, you must make sure that it doesn’t vibrate too much. Don’t underestimate the differences between various models when it comes to vibrations. This will heavily affect your comfort while you are working. Therefore, pay attention to the vibration feature.

7. Weight

Weight is an important factor for those looking for a portable machine. If you don’t plan to carry it around, you don’t have to worry about its weight that much.

8. the Positioning of Control Systems

Control systems are another important feature of a scroll saw. You should buy a model that has ergonomic positioning of control systems. As a result, these machines are easy to operate.

9. Dust Collection System

The way a dust collection system works is very important and this is why the majority of the models on the market come with an integrated DCS. There are two main types – the blow tube type and the compressor system. We recommend you to choose the blow tube, as they provide more flexibility and versatility.

10. Accessories

Accessories can play a very important role for you if you plan to make demanding projects. On the other hand, if you will use it for standard works, you don’t have to pay more for a machine just because it comes with lots of accessories.

Scroll Saw Tips and Techniques for Users

Here are some basic tips and tricks for the scroll saw users. Both hobby and professional users must know these things. Those include checking the blade, checking the teeth, using reverse tooth blades, choosing dry wood for cutting, and preventing splitting, burning, and warping. In addition, these scroll saw tips and scroll saw techniques imply using V-block, benefiting from the grain direction, and avoiding using worn sandpaper. Let’s begin!

1. Checking the Blade and Teeth Before Working

Checking the blade and the teeth before you start your work is very important. You should check it with your thumb. Simply run it up the front of the blade. Make sure that the teeth are pointed down and to the front.

Similarly, you must check the blades. They must be properly secured. Blades must be sharp. Never use a dull or bent blade. You will end up with uneven cuts and might even hurt yourself. Also, check the blades for rust.

2. Using Reverse Tooth Blades

Last 3 teeth at the bottom of the reverse tooth blade are in the opposite direction than the rest of the teeth. This is important for avoiding the burr formation.

3. Choosing Dry Wood for Cutting

Type of wood is one of the most important elements of a successful project. Namely, you should cut dry wood. You should cut it with a dry blade. Moreover, we want you to understand why it has to be dry. You may also get your wood dried at home before using it. Wet wood will lead to deterioration of the blades.

4. Preventing Wood Warping, Splitting and Burning

Preventing wood warping, splitting, and burning is very important for the successful outcome of your project. There are several scroll saw tips and techniques you should follow to achieve that.

First of all, you must always store the wood in a dry place. Also, experts recommend storing it on a flat surface. If you put a heavy piece of wood on top of it, the results will be even better.

Here are some tips on reversing a warped piece of wood. You should dampen its surface with a rag. Then, place it on a flat surface. Put some heavy object on top of it. Let it stay there for at least a week.

You can prevent wood splitting by placing a scrap piece underneath the wood piece before you start the drilling procedure. Also, drill the wood until you see that the point of the bit will break through the surface. Stop, and continue from the other side.

You can prevent the wood from burning by putting a clear packaging tape over the wood pattern. This will help lubricate the blade and preventing burning. Preventing these harms to the wood is a must for amazing scroll saw projects.

5. Using V-Block and Grain Direction as Required

Other important scroll sawing tips refer to using V-block and grain direction. You should use a V-block if you want to cut a rounded wood. Why? In this way, the wood won’t roll into the blade. As a result, you will save it from breaking or jamming up.

You should use grain direction to enhance the quality of your project, depending on the required effect, such as highlighting the particular piece of wood. This scroll saw technique can significantly improve the aesthetic value of your item.

6. Avoiding Worn Sandpaper

Regardless of the situation, you should never use worn sandpaper. Once you notice that the grit is gone, you must use a new piece of sandpaper, as the worn out one will burnish the wood. You can use it only on very sharp parts.

Scroll Sawing Techniques for Advanced Users

Now, we want to introduce you to some advanced scroll saw tips and techniques which only experienced and skilled users should attempt to undertake. Those include cutting multiple pieces simultaneously, taking on double sawing projects, zero clearance, and carving. Let’s learn more about each of these advanced techniques.

1. Cutting Multiple Pieces Simultaneously

Cutting multiple pieces simultaneously is one of the scroll saw tips and techniques for advanced users. This technique is also known as the stack cutting technique. It significantly increases your efficiency. You can save up to 75% of your precious time!

You should first stack the wood pieces. Make sure that the “good” sides are of all the pieces are placed in the same direction. Then, you should place the double-side table between the layers and wrap it around the outer parts. Next, glue the layers together and insert small nails or toothpicks into the cracks.

2. Taking on Double Sawing Projects

Double sawing is one of the advanced scroll sawing technique that refers to making projects that look much better than the projects usually made with a scroll saw. The basic principle implies applying the pattern to two sides of the wood. Then, you should place the crease onto the corner of the blank. Also, make sure that the blank is perfectly square.

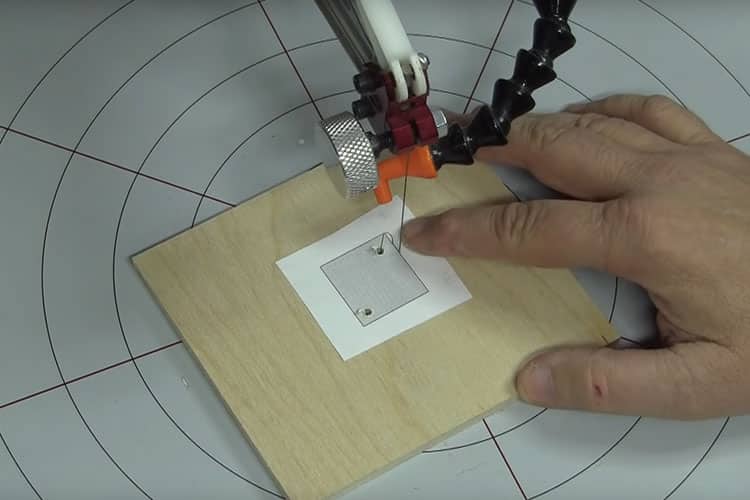

3. Handling a Table Saw Insert with Zero Clearance

Making an insert for a table saw with a DIY zero clearance is an important part of using a scroll saw. Yet, it is among the complicated ones. First, you should know the radius of the semicircular ends of the wooden insert – the elongated hole. You should also derive the distance in between the internal centers.

Constructing the Shape

Now, you can construct the size and shape by using a compass. This part of the job is not demanding at all. You will need a piece that is about 5/8? thick when making an insert. Don’t forget to reinforce the insert with a few splines to prevent splitting.

Then, cut the slots on the ends of the wood. How deep should the slots be? Experts recommend cutting them as steep as possible. You can benefit from using an efficient Tenon jig or clamping the piece on a sturdy block of timber.

Then, glue some hardwood pieces to the slots. You can also use plywood. However, make sure to use a quality one, such as the birch plywood of Baltic. Next, cut out both of the radii and fit them in the wood saw. Also, use a heavy wooden block to restrain the front part. Hold the insert down and use the spinning blade to protrude it. Now you can insert the new insert.

You should drill the holes to make some room for the arbor flange. Finally, you should adjust the insert height. Don’t forget to add a pin to the insert back. This will prevent it from moving from the hole. You should also put several varnish layers on the top and bottom of the insert.

4. Doing the Carving Operations

Carving operations are not difficult at all. However, we have placed them in the advanced skills as all users agree that these are among the most tedious operations. Also, the carving is time-consuming.

Scroll Sawing Tips for the Ultimate Safety

There are different safety tips you should stick to in order to achieve the very best results and stay on the safe side while using a scroll saw. Let’s see what the experts say about safety with this machine.

First of all, scroll saws are the machines that don’t involve much of hazards. There are only two or three safety measures you should follow while using one.

Namely, proper lighting is important for effortless and clear imaging of the pattern lines. This enables making accurate cuts. You should have both fixed and flexible lights. In this way, you will be able to use light from different angles.

Moreover, you should consider using magnification. It can help you work on detailed projects. It will also protect your eyes, and you will be able to work in a relaxed way. You can benefit from glasses, magnifying glass, or magnifying glass mounted on your scroll saw. There are also models with LED lights.

Another important safety tip refers to speed. You should not hurry. Make your cuts in a slow manner to avoid stress, mistakes, and possible injuries.

Scroll Saw Techniques for Maintenance and Troubleshooting

Just like with any other machine, maintenance is very important for scroll saws. Those include lubrication, cleaning, and storing your machine. Let’s learn more about each of these actions.

1. Lubricating the Scroll Saw

Scroll saw tips and tricks always include some lubricating techniques. You should remove the saw covers (found in almost all models). Then, turn the saw on its side. Generously apply the lubricant recommended by the saw manufacturer around the shaft end. Leave the saw in this condition overnight. Repeat this process the next day on the other side of the saw.

2. Cleaning and Storing the Scroll Saw

If your machine doesn’t have a dust collector, you should blow it off after each use. You must prevent dust collection inside and on the machine.

Moreover, apply paste wax on the working table to ensure that your machine glides smoothly. This will prolong its lifetime.

Finally, always turn the machine off and unplug it as soon as your work is finished. Store the machine in its original package.

3. Troubleshooting

You may encounter some common scroll saw issues once in a while. Let’s see what are the most common problems scroll saw users have to troubleshoot.

Scroll saw won’t start: Your cord might be damaged, the switch might be burnt, or the fuse might be tripped. Try fixing these three issues and restart the saw.

The blade is too slow: This problem often occurs if the voltage is low. Resolving this issue allows the blade to come up to the speed.

Saw overload: If your saw stopped working due to an overload, you should turn it off and check for a blown saw fuse. Repairing the fuse resolves this issue.

Finally, we want to emphasize once again that experts strongly recommend being attentive to the above tips and tricks. In this way, you can do anything you want with a scroll saw. Remember that your successful journey with a scroll saw starts with a proper buying process. Furthermore, you must master the scroll saw tips and techniques related to using, maintaining, caring, and safekeeping the scroll saw. As a result, you will be proud of making beautiful, creative, and fantastic items.