A pipe wrench or spud wrench is a common tool that can be seen in any handyman or DIY enthusiast’s arsenal. But how do they differ?

In short, both have similar applications and almost the same level of output. But pipe wrenches are a bit more convenient than spud wrenches because they have stronger grips and more torque!

Let’s get to the details!

Spud Wrenches

Spud wrenches have one adjustable head on one side and a tapered spike on another. The head is mainly used to tighten or loosen nuts and spike lines up the bolts.

Spud wrenches have one adjustable head on one side and a tapered spike on another. The head is mainly used to tighten or loosen nuts and spike lines up the bolts.

Where to use a spud wrench?

Initially they were used to twist and tighten small nuts of toilet pipes and those nuts were called spuds. Since 2010, the modern toilets stopped requiring these nuts.

However, spud wrenches have made their own space in other sectors. For example, construction workers now use them to connect the beams together.

How? Steel beams have holes at the end to connect with another beam. The workers put the spiked end in two holes of two different beams to align and then they attach them together with a bolt.

Pipefitter and steamfitter also use this type of wrench in similar ways.

How a spud wrench works

Watch the video to understand how to work with a spud wrench.

Types of spud wrenches

1. Construction Wrenches

a) Adjustable or Crescent Spud Wrench

One side of their head is fixed and another side is fixable according to the nut’s size (8 to 11 inches)

However, twisting bolts with them is difficult compared to the fixed-head wrenches.

b) Plumber’s Spud Wrench

You need them for toilet spuds and sink pipe bolts because these bolts fit perfectly with this type.

Also, they are less adaptable among the wrenches.

i) Internal spud wrench

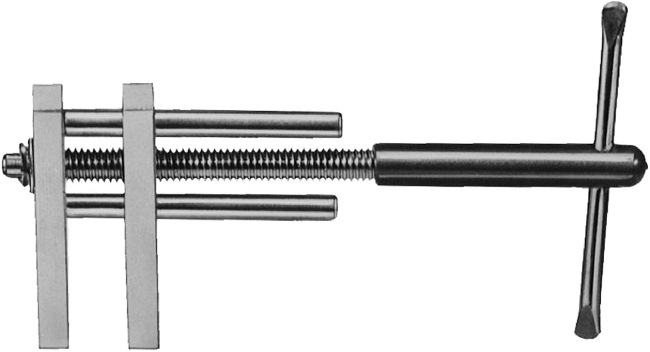

They twist the bolt from inside and are adjustable according to the size of the bolt.

ii) External spud wrench

They are useful for tightening and holding big nuts, grasp pipes and bolts. Just like the internal ones, they are expandable too.

iii) Adjustable Plumbing Spud Wrench

This versatile tool can work with a huge range of pipes and bolts because of being easily adjustable.

But the only problem is their grip is not as strong as their fixed-headed counterparts.

c) Offset Spud Wrench

Look at them and you will find their thinner spiked tail. This means they are able to line up smaller bolts than others.

Similarly, their grip on bolts are also stronger. In fact, their curved heads help speed up the fastening or loosening process of the bolt manifold.

However, they won’t work as flat as pancakes on square shaped bolts like they will do on round headed bolts.

2. Radiator Spud Wrench

The length of this wrench is 1.5 to 2 inches and it performs with radiator valves only.

3. Ratchet Spud Wrench

Double socket ratchet spud wrench

They have two sides open to adjust the bolts and the grip is strong. With 13 inches length and 2.20 to 2.4 pounds of weight, they work real fast.

Single head ratchet spud wrench

As the name suggests, they have one side open to adjust bolts and small bolts can be adjusted with this type only.

How to Use a Spud Wrench

Step 1: Place the wrench around the bolt

Step 2: If the grip is loose, place a coin in between the wrench and the bolt.

Step 3: Now move the wrench accordingly (to tighten or to loosen)

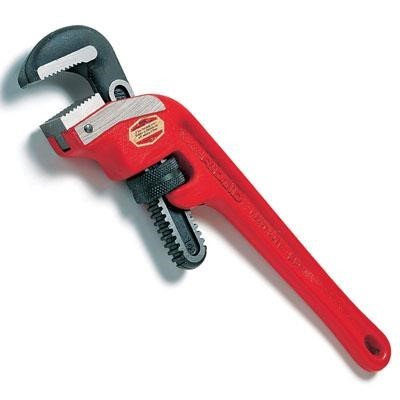

Pipe Wrench or Monkey Wrench or Stillson Wrench

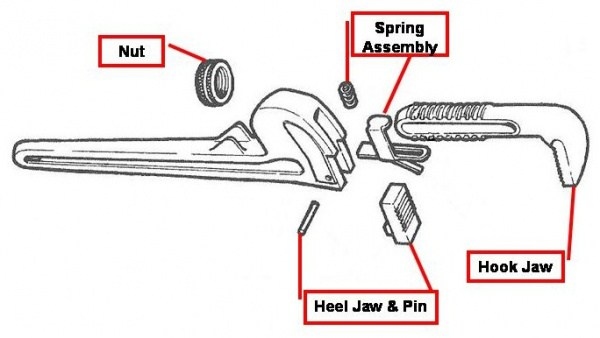

Like a ratchet wrench, they only grip when you turn the wrench in one direction. The hook jaw and the heel jaw create the grip on the pipe.

Where to use them?

They are used for pipes e.g. black iron or other metal pipes or galvanized steel.

There are different types of these wrenches for six different types of pipes.

For instance, the end pipe wrench is for end pipes while the offset wrench is perfect for difficult angles and narrow spaces. On the other hand, the compound leverage wrench takes care of the seized joints.

Types of pipe wrenches

Strap wrench

They have unique heads (made of rubber/ leather/ chain or other strong fabrics) but the usual handlebars though operating them is easy.

Just wrap the pipe with the belt of the wrench, adjust them and then turn the handlebar.

Watch this video if you need more instructions:

Offset wrench

They have an offset of 90-degree angle. The jaws are different though they look like an end pipe wrench.

Just to inform you, the bigger size can be upto 48 inches.

End pipe wrench

Their angular jaw is specially designed to have a grip on the tough end pipes in narrow spaces.

Straight pipe wrench

8 to 24 inches long, this is the most-favorites of plumbers. The design is quite simple with a parallel head and handle to ensure maximum grip on the pipes.

Compound leverage wrench

Compound leverage wrenches were invented to provide the maximum torque and leverage needed to work with seized joints.

You probably know that the seized joints are often damaged by cold weather or age.

This powerful wrench can create 14 times more pressure on the pipe than a standard pipe wrench and is specially designed for quick recovery.

How to Use a Pipe Wrench?

There are five types of pipe wrenches that are slightly different from each other with different angles of hook and heel jaw.

Among them, the strap wrench has a completely different-looking head and we’ve mentioned earlier how to operate them

Step 1: The thumb rule is, place the pipe in between hook and heel jaw

Step 2: Adjust the nut to get the best possible grip

Step 3: Move the handle to tighten or loosen

Pros and Cons

Pipe Wrench Pros

- Compress the pipe to block slipping

- Good to go with plumbing works

- Better grip than spud wrench

- Similarly fastens better too

Pipe Wrench Cons

- Can’t line up bolts

Spud wrench Pros

- Good for tightening the bolts

- Preferable for auto mechanic work

- Helps in lining up the bolt with their spike ends

Spud wrench Cons

- Weaker grip over the nuts

Which One Should You Take for Your Next Project?

Both of them have similar applications and they work just fine under similar situations.

For example, their adjustable heads work effectively on a socket, bolts, and pipe fitting. In fact, pipe and spud wrenches have similar size charts for sockets.

However, pipe wrenches will be a bit more useful than spud wrenches with their stronger grip and more torque.