Both bench grinder and angle grinder are familiar to most metalworkers across the globe. This might be true that both are used in similar activities, there are a couple of differences that sets these two power tools apart. Bench grinder is stationary whereas angle grinders are portable.

Let’s discuss about all the differences between the bench grinder and angle grinder in details and find out the best tool for your metalworking needs. Here goes

Bench Grinder vs Angle Grinder: How Do They Differ?

Applications

- Bench Grinder

Bench grinders are ideal machines for grinding, cutting, brushing up, sharpening metal objects, removing rust, buffing, shaping, and polishing surfaces. If the size of your workpiece requires 2 hands to get the right edge, a bench grinder is your best bet for the job. For instance, when you need to sharpen a lawnmower blade. You can utilize the device to perform different tasks just by switching between the various disc types.

- Angle Grinder

Angle grinders are great for so many jobs, such as removing paint and rust from metal surfaces, removing mortars, cutting ceramic and stones, cleaning and cutting metal objects, sharpening tools, smoothening and carving wood.

You can apply this machine to numerous projects for a wide variety of tasks and get great results. All you need to do is to use the right disc type for the particular task.

Design

- Bench Grinder

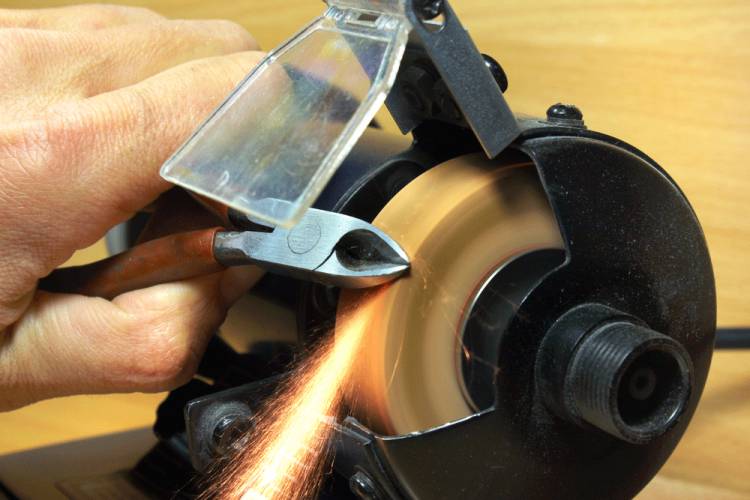

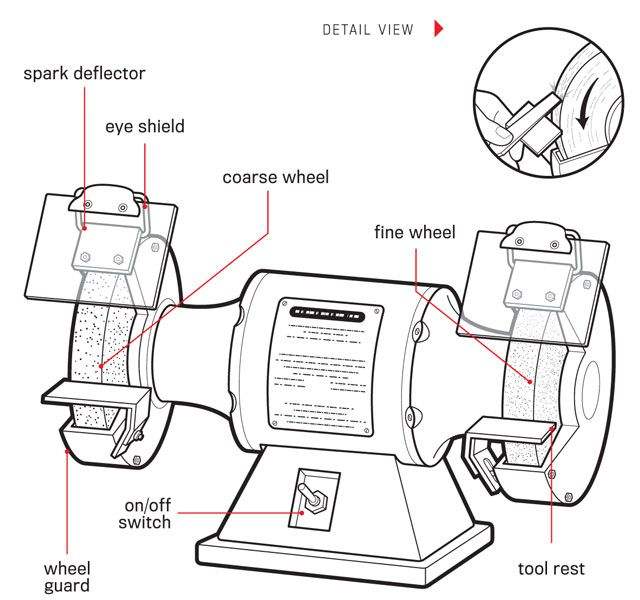

The name says it all, the power tool sits on your workbench and uses two powerful abrasive wheels to shape metals and sharpen other tools such as chisels, drill bits, and axes. Bench grinders are designed to stabilize on a flat surface and minimalize vibration. When operating with a bench grinder, you bring the workpieces to the grinder to work on them.

- Angle Grinder

In contrast, Angle grinders are handheld rotary tools that use a single disc for cutting, grinding, and polishing. They have both corded and cordless options and include a good amount of grip on the handle that allows you to maneuver into tight corners effortlessly as well as helps minimalize vibrations.

Speed & Vibrations

- Bench Grinder

Bench grinders usually have a disc spinning speed ranging from 3,000 to 3,500 rpm. The good thing about these grinders is that when it comes to sharpening, most of them can run slow; at about 1,750 rpm to let you get the most perfection.

With speed, comes vibrations. It’s the same with every tool. But bench grinders have the edge here as they’re intended to be used on flat surfaces. The combined weight of the grinder and the bench work together to reduce vibrations.

- Angle Grinder

Angle grinders are way faster when compared with bench grinders. They typically spin their discs at 8,000 to 12,000 rpm. Imagine the vibration that would cause on the object and your hands.

Since angle grinders are powerful handheld power tools, you feel all of the vibration in your arms and shoulders while using them. However, with speed that great; you spend less time and get more done.

Portability

- Bench Grinder

A bench grinder is not a tool that you pack in the bag every day and leave for work. Rather it’s a device that belongs to a workstation because of its weight. Most bench grinders weigh nearly 40lbs. You can get yourself set and take them to the worksite in case you have some frequent precision grinding tasks to do.

- Angle Grinder

Angle grinders are not stationary machines like their bench alternatives. They’re handheld, lightweight, and compact power tools with an average weight of around 8lbs. These are the kind of grinders you carry to your job sites every day.

Number of wheels

- Bench Grinder

All bench grinders have 2 different rotary discs that can be utilized at once. It makes a huge difference to be able to work with 2 different wheels to get 2 different jobs done at the same time and that you don’t need to change your wheels as frequently as you might need in angle grinders.

- Angle Grinder

Angle grinders lack the facility of having more than one disc utilized simultaneously. They can only operate with one single wheel at a time requiring you to switch between your wheels for different tasks which will cost you time and effort at a work site.

Versatility

- Bench Grinder

The bench grinders work well for shaping and sharpening tools and materials but are not as versatile as angle grinders. You can cover some pretty precise grinding tasks and have multiple choices of wheels to get what you want. The inflexible thing is that you’ll need to work and be around these immobile machines for the most part.

- Angle Grinder

Angle grinders are one of the most versatile rotary power tools you can get. Not just grinding, they are strong enough for cutting different materials including tough metals. Compact design and portability enable them to outshine bench grinders when it comes to versatility.

Price

- Bench Grinder

A bench grinder may cost you between $70 to $700 depending on the brand, size, and options you get along with it.

- Angle Grinder

On the contrary, you can get an angle grinder for $40 to $300 depending on the brand, built quality, and features.

Bench Grinder: Pros and cons

Pros

- Extremely powerful and easy to replace motors

- Slow and fast speed levels

- Cast iron base to control vibration

- Some units are generator-powered

- Great stability

- Awesome safety features

- A large variety of discs to choose from

Cons

- Not suitable for all users

- The tool slows down when the pressure on the disc is high

- Parts are mostly substandard

- Discs require constant modification

- Quite costly

Angle Grinder: Pros and cons

Pros

- Highly portable tool

- Discs are fast-spinning

- Trigger lock

- Superb maneuverability in unusual angles and tight corners

- Simple to change discs

- Easy to handle & user friendly

- Vibration protection

Cons

- Beginners may go through a learning curve

- Overheating occurs too quickly

- The spindle feels excessively long in certain conditions

- Poor quality built-material

When should you get a bench grinder?

Ask yourself what exactly you’ll be using the grinder for, think it through. Choose a bench grinder when you need to sharpen saw blades, drill bits, knives, axes, or shape metal pieces and polish them. If you see yourself trimming the edges of your workpieces on the workbench quite often or want perfection while sharpening other tools, deciding on a bench grinder would be wise.

When should you get an angle grinder?

If you need a versatile grinder that you can take to the worksite and cut rebars, metal pipes, and pavers, then you can’t go wrong with an angle grinder. It will also help you remove paints and mortar, polish stones, restore old metal items and sharpen tools.

FAQs:

1. What is a bench grinder good for?

Ans: For polishing and shaping objects, sharpening other tools and materials precisely in your workshop.

2. Which brand is best for the angle grinder?

Ans: Makita, Dewalt, Bosch, Milwaukee, Black+Decker, Metabo, Kimo, and Avid are some of the best brands you can trust when choosing your angle grinder.

3. Can a bench grinder cut metal?

Ans: If you remove the thick grinding wheel and install a thin cutoff wheel into your bench grinder, it’ll allow you to make some controlled cuts on metals such as sheet metal and pipes.

4. Is a 6 or 8-inch bench grinder better?

Ans: 8-inch is best for heavy-duty work and professional jobs. But 6-inch is more compact and easier to use.