Sanding is not everyone’s favorite activity, but it must be done. The question is, which sander is better for your needs? These tools work similarly and the differences between them are not common knowledge. How do you decide between a drum sander and a planer? Comparison is the way to answer that question.

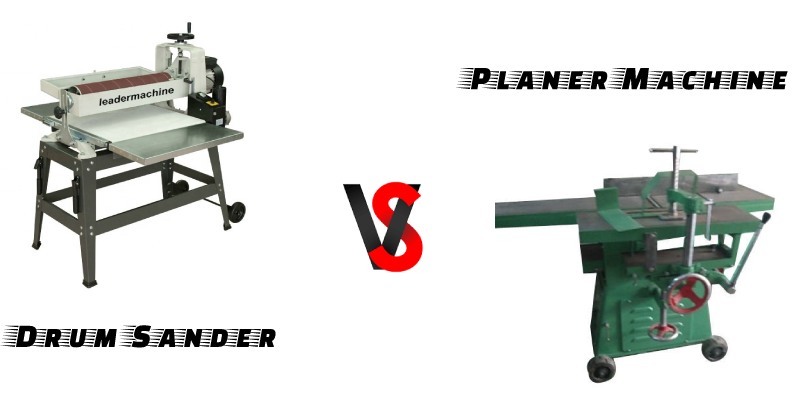

Drum Sander Vs Planer – Key Difference

1. Features

Drum sanders are typically made in widths of 8 to 12 inches. They use wide sandpaper which must be slid around a drum. This is a large piece of equipment and transporting it is difficult. These machines require more passes to achieve the result that you would with one pass of a planer.

Planers, unlike drum sanders, use knives to cut away at the surface of the material you are working on. They can remove a significant amount of material in one pass compared to a drum sander. Both planers and drum sanders can be fit with a dust bag to reduce mess and health risk.

2. Uses

Drum sanders are used to sand large areas and can also be used for fine surfacing or wood sanding. They remove smaller amounts of material compared to a planer which is why they are ideal for finishing and surfacing. Sometimes, another type of sander is needed for finishing after using a drum sander.

Planers are ideal for leveling uneven surfaces quickly such as uneven pieces of plywood. It can do more in less time if compared to a drum sander and it requires less effort. Planers are also used for wood milling which is required for manufacturing furniture. A drum sander would be quite useless in this case.

3. Working Mechanism

Drum sanders work by moving a loop of sandpaper around the drum continuously. This allows is to rip into wood and remove as much of it as you see fit. It cannot remove the same thickness of material as a planer can, but it is still easier to make mistakes with a drum sander because of the way that it works.

Planers work by rotating a drum or head that has blades attached to it. It is used for leveling surfaces by cutting away wood that is the same thickness as the difference in height between the back and front shoes. This allows for even removal without leaving dents and depressions that are different depths.

4. Pros

Drum sanders better for finishing pieces finely and smoothly. When used correctly they can provide amazing finishes. These tools are better for work that requires some amount of precision such as leveling uneven surfaces.

Planers have wide soles and are extremely fast tools to use. They remove more material compared to a drum sander in a faster amount of time. In the time it would take for a drum sander to remove the amount of material that you could remove in a single pass with a planer, you could pass the planer 24 more times.

5. Cons

Drum sanders can be used to thickness boards just like planers but it would take a considerable amount of time. They should not be used without a dust bag as this can create a mess as well. Having to change sandpaper is time consuming in comparison to planers. Blades on planers do not need replacing as frequently as sandpaper does.

Planers, especially the benchtop planers require a certain amount of skill to use just like drum sanders. These machines create a lot of mess and chips can be blown out around your workspace. Motor operated planers can easily make mistakes due to human error. These mistakes are difficult to rectify, whereas with drum sanders mistakes can be fixed more easily.

Who’s the Winner?

The machine that you should choose is entirely dependent on the job that you want to do and the time that you want to take doing it. Both drum sanders and planers have pros and cons, but they are both functional in their intended jobs.

The results that you obtain when using these tools also depends on your skill level as a woodworker. Professionals will get a better result than DIYers, for example. If used correctly and while following guidelines, both tools can be winners.

Comparison Chart

Criteria |

Drum sander |

Planer |

| size | Big | Small |

| weight | Heavier | Lighter |

| portability | Cumbersome to move around | Handheld and portable |

| cutting action | Aggressive or linear | Swift |

| versatility | One design | Electrical and non-electrical designs |

| applicability | Heavy-duty finishes | Leveling |

| speed | Faster for large areas | Fast for leveling wood |

| surface type | Flooring | Wood |

| noise | Loud | Loud |

Conclusion

Whilst both drum sanders and planers have similar functions, it is important to consider the type of work you want done. Do not use one in place of the other. If funds are an issue, you can always rent machinery. Acquaint yourself with use and safety tips before touching wood and always sand safely.

FAQs

1. Is a planer the same as a sander?

Ans. Planers work by spinning hardened steel knives at high speed. This can remove a significant amount of material with one pass. Sanders, on the other hand, work by spinning belts of sandpaper with rollers powered by a motor. They do a similar job, but a planer is faster.

2. Do you have to sand after using a planer?

Ans. Scraping or sanding a surface after using a planer is recommended if you want to apply a finish. This is because planers leave behind machine marks which ruin the look of the surface. Sanding is not required if you want to finish with thick paint.

3. Does a planer make wood smooth?

Ans. When used correctly or in a certain way, planers can make wood flat and smooth. It would be easier to sand after using a planer to get a smooth finish, but a planer can suffice if you do not have access to a sander.

4. Can you use a planer to remove old finish?

Ans. Although removing old finish with a planer is possible, it’s not recommended. This is because it can melt some finished with friction, thus ruining the blades. A belt sander is recommended at half speed in order to remove old finish.