A planer is one of the essential carpentry tools used for perfecting the thickness of a workpiece. For any wooden craft or furniture that requires evenly thick pieces in action, a planer stands better than most. Using either mechanical settings or manual pressure (by the user), a wood planer may work wonder if put to use correctly, and this is what raises the question among carpenters or DIY woodworkers if they should learn how it works. So, how does a planer work and how can you use it to your advantages?

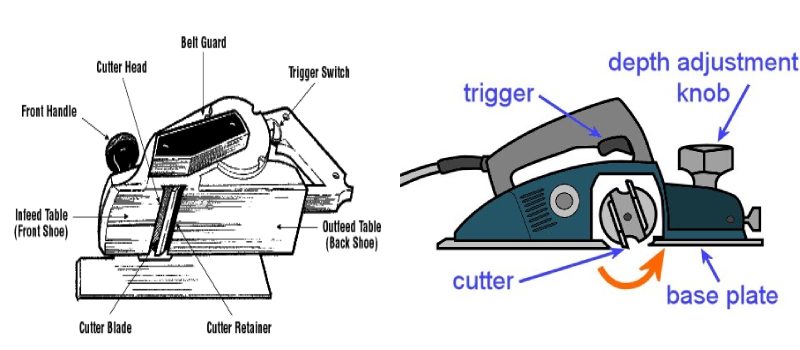

The very first thing that matters is absolute familiarity with the various parts and the basic mechanism. There you go…

Recognizing the Parts and Their Basics

To further help answer the question ‘how does a plane work’, we’ll highlight the parts of a planer as well as a few more details about each of them in this segment as follows:

1. Bed and Tables

The bed is essentially the base of the benchtop planer machine. It houses a number of important components and mechanisms needed for the planer to function. The table is situated right over it. It provides a mechanism to clamp down on the piece of wood being worked on as well as making movements that correspond to that of its base.

2. Housings

These are the solid and robust columns found on either side of the base of the planer. They provide support for other mechanisms on the planer to work on the piece of wood being worked on.

3. Cross Rail

This part of the planer is held up by the housing component listed above. They are fitted along with a groove so as to allow for its vertical movements. These movements are so that they can be able to allow for the accommodation of pieces of varying heights.

4. Tool Heads

This is the part of the planer that holds the element that actually chips away at the wood so as to attain the desired uniform thickness. They are placed along both horizontal and vertical cross rails. Depending on the required needs, these parts can be adjusted so as to attain angled planning on the wood piece.

5. Driving Portion

This part of the planer is located on the table’s underside. It is responsible for moving the table and can be powered up using a number of means.

6. Feed Mechanism

As the name suggests, this part is responsible for feeding the wood pieces into the planer. It carries the wood in, carrying it through the planer where it gets worked on and eventually ‘feeds’ out the worked on a piece of wood on the other end.

How Does a Planer Work?

Planers are of different types and styles and you may move onto how a wood planer works after learning a few details. From the above section, some insight into its working can be gleaned.

Basically, the piece of wood that needs to be worked on is first inspected for other problems like damages or the presence of other unneeded material. Thereafter, measurements are taken to determine the amount of shaving or chipping that is needed to be done.

The wood is then fed to the planer where the blade(s) go to action chipping away at the wood leaving a clean smooth surface on the wood and a uniform thickness all round as desired.

Functions of Handheld and Stationary Planers Explained

In the case of stationary planers, the blades to work on the wood are located at the base of the machine. This type is most preferred when handling large sized wood pieces so as to achieve uniformity faster and more accurate. You need to set it up with different settings so that you can adjust the depth of the chipping you want.

Handheld planers, on the other hand, offer another aspect to woodworking. Unlike the model above, you get to see the desired thickness attained after each stroke or swing of the planer. In the model above, after feeding the wood to it, you have to wait for the end product to see if it did indeed get to the thickness being aimed for.

How a Planer Works When Versatile Applications Are Intended

Planers have proven to be quite versatile in the number of ways they can be used to attain a uniform thickness or flatness. This tool is a great piece among other stationary machines. We’ll discuss a few of the applications of a planer in the following section.

1. Planning the Wood Ends

While working on any piece of wood using a planer, planning the wood ends is almost always the last step.

Planning the ends requires the deftest of touches since it is quite prone to tearing and as such well-calculated motions from either your hand plane or another type of planer are needed for desired results.

For small pieces, a hand planer would be most ideal. So, finding out the answers to ‘how does a hand planer work’ would prove useful.

2. Flattening the Uneven Work Pieces

It’s a fact that a lot of the timber or wood pieces we buy don’t come in even, flat specs. So if you were also wondering how does a wood planer work for this kind of scenario, here it is.

Try first to find the side that is ‘flattest’ in this case, and lay that side down on the bed of the planer. The rougher side gets flattened out first and then it can be flipped to flatten the other side. Doing this ensures you attain a good degree of evenness from the piece of wood.

3. Reclaiming Old Wood

This is a particularly useful application for planers since a lot of old wood ends up being wasted away.

To reclaim old wood using a planer, first, remove everything embedded in the wood that isn’t originally part of it. Thereafter, you can set the wood on your planer and work at it till you attain your desired thickness and look.

4. Doing the ‘Thickness’ Job

When getting wood for your project, they may not always come in the thickness required for the job. It is the work of the planer to get the wood down to the right uniform thickness needed.

After getting the wood for the project, measure out the needed thickness dimensions and mark them out if you’re using a hand planer. With planers, either a high-precision hand planer or an automatic model, you can adjust the measurements easily and achieve uniformity faster.

Having read this to answer the question ‘how does a planer work’, you have hopefully gained more insight into the workings and mechanisms of a planer. To further help your cause in properly understanding this piece of equipment, it would be prudent to read up a little more about it.

This way you can find out more ways in which it can be applied to various situations, furthering your ability for successful projects. Finding out more about how works a hand planer will also give you a safety edge so that you can rest assured you know how to properly handle it and address any complications that can arise from its use without putting yourself at risk of injury.