Gone are the days when a swordsmith would spend hours grinding their knives sharp. The days of an artisan scraping away at wooden planks are long gone. Now is the era of electronics and thus, enter Sanders. These machines use motors to do the sanding for you so that you don’t have to.

Although these power tools have made our jobs significantly easier, they also came with a few new sets of skills and knowledge that one would require to make good use of them. After all, chipping away at the metal with a file wouldn’t be able to take a finger off like sandpaper moving at 300 feet per second. One has to be careful.

Unfortunately, skills are something that we cannot impart through a few mere lines of text, despite what many “how-to” books would have you believe to be possible. On that, you’re on your own. However, you are going to need to know which wood sander types you’re going to have to get started with if you are to start practicing and honing your skills. So, we came up with this article to impart our knowledge of the sanders, so that you know where to start.

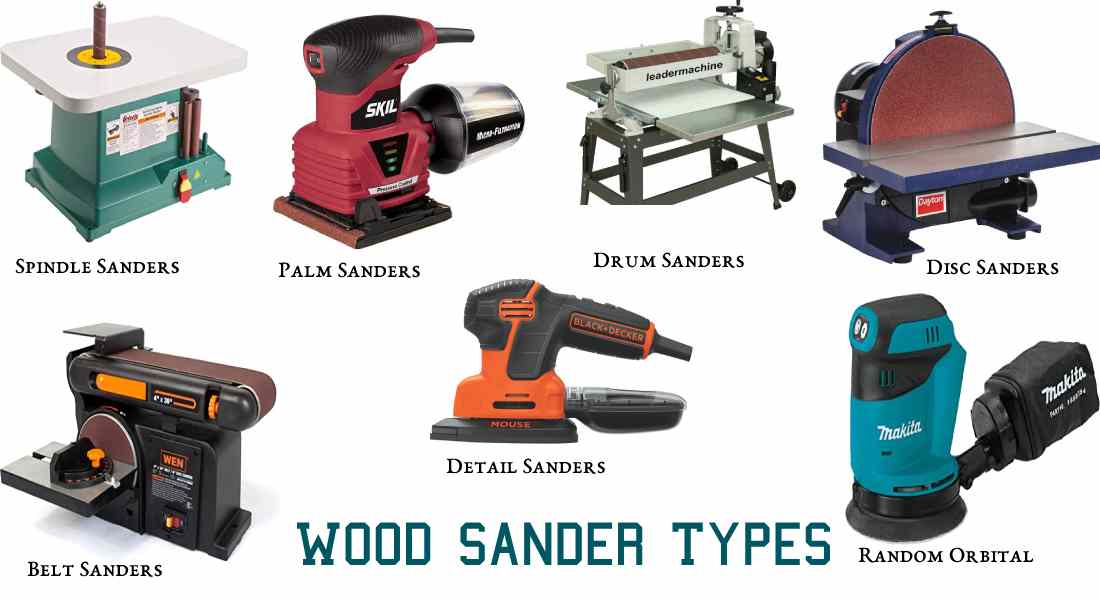

7 Different Types of Sanders

Sanders, regardless of their types, have a basic principle: They use motors to run a strip or a flat piece of sandpaper in a specific direction at high speeds, so that any materials touching it, gets stripped. The type of motors, sandpaper, and rotation determines the wood sander types and their ease of use. The main types are:

Belt Sanders: A long strip of sandpaper attached to a belt that moves at a high speed through the use of rollers.

Disc Sanders: A sheet of sandpaper is connected to a disc that rotates at a high speed.

Spindle Sanders: These tools will hold a large strip of sandpaper on a spindle that will rotate at high speeds and oscillate up and down.

Random Orbital: These sanders have a flat, circular surface to attach a sheet of sandpaper to. Once attached, the surface will rotate while moving around in a random orbital motion.

Palm Sanders: Palm Sanders uses small square pieces of sandpaper onto a surface that rotates in a fixed orbital motion. These can be handheld and small enough in size to be used with much more ease and convenience.

Drum Sanders: These are industrial-grade sanders that have rotating drums with a wide belt sander strip covering the drums.

Detail Sanders: These devices are similar to palm sanders, however, they come in a different, triangular shape. They can be used for more delicate tasks where other sanders cannot reach.

Types of Sanders – Which One Should I Choose?

This is a question that has no easy answer. All types of sanders come with their own sets of pros and cons. Otherwise, there’d be only one type out there. Regardless, if we understand the pros and cons, we’d know which one would be the most suitable for our needs.

Belt Sanders

Belt sanders are usually placed on a fixed surface. So, you can just turn on the sander and work on it without any more interaction with it. The belt sander belts would rotate by themselves, freeing up both your hands to focus on your project. Unlike traditional sanding or scraping, this requires you to hold the project to the sandpaper instead of the other way around. However, the non-stationary ones can also be used to polish surfaces by holding the sander onto the surfaces instead.

These types of sanders are best used for sharpening knives or scraping flat wood surfaces before a project. The downside of these types of sanders is that they are small, they are not powerful enough to do anything more than polish metal. So, if you’re looking to use it for the metalworking, you’d be better off going for a grinder instead. But if you’re looking for an effective sharpener, this would do the trick.

Spindle Sanders

Also known as Oscillating Spindle Sanders, these devices come with an upright spindle that rotates and oscillates up and down with sandpaper attached to it. This shape allows you to strip off the wood with unmatched precision, allowing you to make smooth curves and shapes. Its cylindrical shape ensures that only a small portion of the surface on the circumference touches your project, giving you more control over your shaping. However, this sander is the worst type for sanding large, flat surfaces. You’d be better off using a belt or disc sander for that purpose instead.

Random Orbital Sanders

The main feature of Random Orbital Sanders is the “random” part. Since this sander has a rotating disc with a sheet of sandpaper attached to it, it can be used to polish surfaces like floors or flat pieces of wood. However, since its rotation is also accompanied by a random orbital motion, it ensures that the wood remains free of any visible patterns or scraping marks, giving it a more aesthetically pleasing finish. These are best used for polishing floors and chair/table surfaces. But you must control the wood dust produced by random orbital sanders to prevent adverse health effects.

Disc Sanders

Disc Sanders are extremely effective tools for shaping and scraping edges. Its upright position allows you to place pieces of wood and other materials in place and have its edges stripped gradually. You can even use them to shorten the edges by a few centimeters when you need to make that tight fit. They are relatively safer than belt sanders and can provide a very smooth finish and thus are used for removing varnish, glue, and rust. The downsides are that they cannot be used for shaping or sanding surfaces like a table or the floor.

Drum Sanders

Versatile tools that can be used for both shaping, smoothing, and scraping surfaces. Although this type of sander requires a bit more skill to use, with proper experience, it can be a good substitute for all of the above (except for palm sanders and random orbital sanders). However, they tend to be a bit more pricey compared to a similar quality sander of any other type. These can give you a consistent finish, each time, every time.

Detail Sanders

As the name suggests, this sander is all about detailing and providing finishing touches. With a triangular-shaped sanding surface, this one can provide a sharp, pointy edge for precision sanding. Thus, these are best used for sanding corners or hard-to-reach places. Apart from this feature, these are fairly similar to palm sanders, barring the fact that they tend to be a lot noisier.

Palm Sanders

It’s a compact, portable type of sander that is extremely easy to use, relatively safer, and great for polishing. However, these won’t be the best choice for using low grit sandpaper to take off rough surfaces. You should better stick to polishing tasks and use sandpaper properly with one of these babies.

To conclude this article, all we’re going to say is that each of the wood sander types has its own set of pros and cons and its own set of uses. There are also types of sanders that are either a composition or a variation of the sanders above, like the belt-disc sander (a combination of both belt and disc sanders) and the orbital sander (without the random motion). But we mostly preferred to stick to the general types in this article and hopefully, you will be able to tell which is which from just the descriptions we’ve placed above.