If you’re not sure about the rebar size you should choose for your concrete slab, the answer lies in the type of use you have planned for the concrete slab. Usually, a slab-built over the ground will have fundamental support from below and can do without rebars. A slab with a thickness below 4” won’t require rebars as well.

The strength, rating, and amount of rebars you’re going to need will increase depending on the load you intend to support over the slab. The placement of the rebars is important too.

What Size Rebar for Concrete Slab?

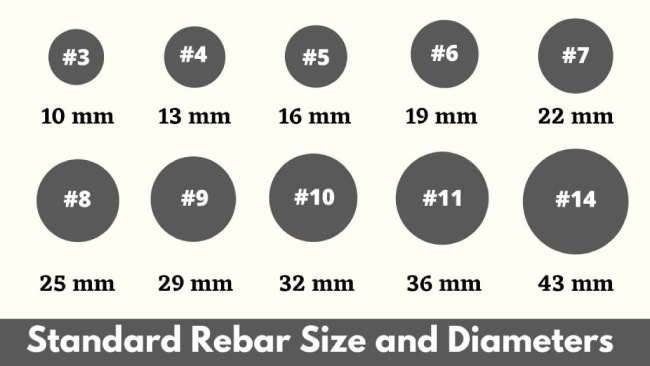

This usually depends on the intended workload. If you are trying to put a new concrete slab on your small-scale domestic project; 6mm (#19), 8mm (#25), and 10mm (#32) rebars will do the job nicely.

Smaller projects like this usually have to sustain minimal loads and a lower tensile strength is more than enough to keep your slab working for a long time. For example, driveways and patios often use the lightest 6mm rebars.

On the flip side, if you’re constructing walls, piers, columns, footings, or foundations, rebars with higher strength are required. It is recommended to use 8mm+ rebars in walls, piers, or columns; and 10mm+ rebars for footings or foundations.

However, it’s crucial to check your local building code before you start pouring the concrete. Every state or region has a building code, instructed by the American Concrete Institute (ACI) that’s mandatory to follow.

Why is it important?

Rebars are used to add tensile strength to concrete so the concrete doesn’t have cracks over time with uneven areas. The size of the rebar you use will determine how much weight and pressure your concrete slab can hold.

As a result, the thicker your rebars, the more load your concrete slab will be able to handle without shifting, cracking, or breaking.

However, rebars aren’t necessary if the slab you’re making is thinner than 4 inches. Anything thicker than that will need reinforcing. Finding the right rebar size for your concrete slab can also save you money. You don’t need an 8mm Rebar on your 4” thick slab.

This video shows different aspects of selecting rebars for a driveway:

hoosing the perfect rebar will not only help increase the yield strength of your concrete, but it may also help you save some money since the wider the rebar is, the more it’ll cost you.

However, something worse can happen if you use rebars too small for your slab. It can threaten the integrity of the whole slab, making it crumble underneath the weight. This will damage the property, belongings, and people.

That’s why choosing the ideal rebar size for your concrete slab is crucial.

Common rebar sizes

Rebars usually come in the shape of 20-feet long rods. Most of them have ribs all over their body to increase the grip of the concrete. They are usually known as “deformed bars.” The primary measurement is the width of the rebar’s diameter.

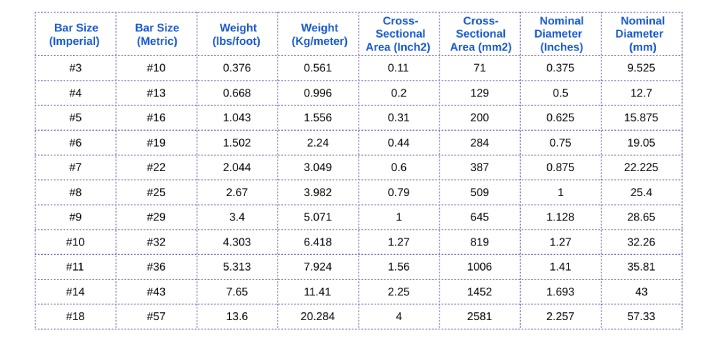

The ribs aren’t included in the measurement and the diameter is expressed in eighths of an inch. For example, a size 4 rebar will have a diameter of 4/8” or ½ inches. Similarly, rebar with a size 15 will be 15/8 inches.

Here’s a complete chart of different rebar sizes, their diameters, and weight:

Rebar markings

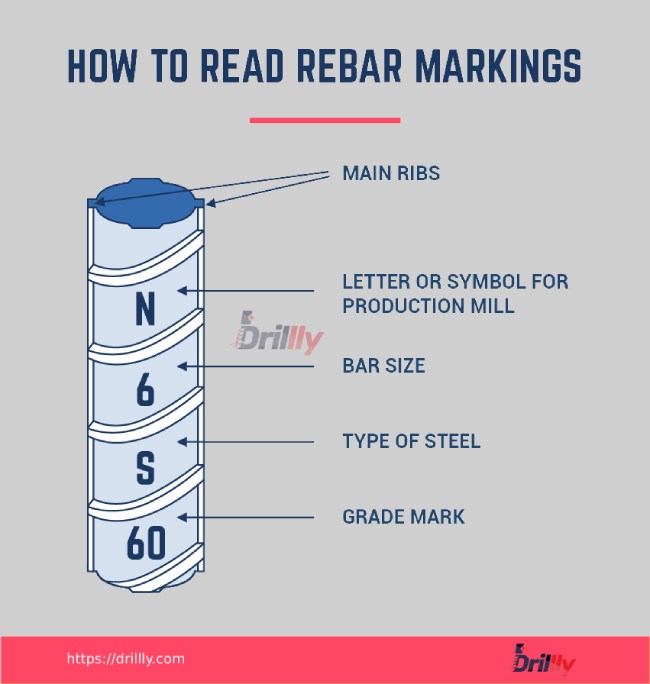

Each rod of the rebar is engraved with a marking with a code instructed by the American Society for Testing and Materials (ASTM). These markings showcase the mill, bar size, metal type, and grade designation. There are 4 marks and here’s how to read them:

The first marker refers to the mill and it is expressed by a letter or a symbol. A company can set different markers for different mills.

The second marker expresses the bar size and is demonstrated by a number. The number ranges from 10-to 36, 43, and 57 for metric measurement. The numbers can also be in inch-lbs marking (the imperial system) and range from 3 to 11, 14, and 18.

The 3rd marker represents the type of steel and the last marker refers to the grade designation. You can decode the rebar markings for better understanding.

Benefits of using rebar

- Improves structural support

- Increases tensile strength

- Manages stress efficiently

- Reduce concrete shrinkage

- Keep the cracks to the minimum

- Improves weight distribution

- Steel can be recycled

- Easily available

- Provides ductility to the structure

- Tough and durable

Risks of using Rebar

- Can reduce the load-bearing capability if placed incorrectly

- Prone to heat damage

- Prone to rust if exposed to oxygen

- Expensive

- Adds weight to the structure

- Can’t stop cracks from forming

How to place rebar in concrete?

There are a number of things to consider before placing the rebar in concrete. Here is the best way to put the framework in –

FAQs

1. Can I pour concrete without rebars?

Ans: Technically, yes. Not all kinds of concrete structures require additional protection from rebars. If the slab you’re about to make is under 4” in thickness, reinforced by a compacted base, and isn’t expected to sustain heavy loads, rebars won’t be necessary.

2. Can I weld epoxy-coated steel?

Ans: Yes but you need to follow the guidelines provided by the American Welding Society. Some rebars may need preheating to up to 500° F and you need to repair the damaged areas using patch materials that meet ASTM A7 requirements once the job is done.

3. How much rebar is needed for a concrete slab?

Ans: The common practice is to use one stick of rebar for every 8 inches of footing width. If your footings are 16” wide, you’ll need 2 additional sticks of rebar along the width of the footing. The number of additional sticks will be 3 in case your footings are 24” wide.

4. Does rebar rust in concrete?

Ans: Technically, no. The alkaline environment and the protection from the concrete keep oxygen away from the rebars and no rust can occur without oxygen.

However, if the concrete gets cracked, water and vapor can get to the exposed rebars and cause them to rust over time.