Wood routers are essential woodworking tools commonly used to add decorative details to define and enhance the final appearance of your project. They are commonly used in carpentry, cabinetry, and boat building.

Here we’ll introduce you to all the types of wood routers out there so you can easily decide on the right type routers to get for your own woodworking needs.

Standard Types of Wood Routers

a) Fixed-Base Routers

Fixed-base routers have both the body and base at a fixed position with a motor moving up and down. Once you adjust the device at its fixed cutting depth and lock the motor, you cannot make further changes when using the tool. They are suitable for beginners because they can handle them well due to their lightweight and simple functioning. They are best for tasks that need linear movements, such as edge shaping or general profiling.

| Pros | Cons |

|---|---|

| 1. Give you better control due to an accurate handle placement at the lower part of the base. | 1. Cannot create intricate designs in woodworking. |

| 2. Can route repeatedly without worrying about the cutting depth that remains the same. | 2. A bit time-consuming because you need to change the cutting depth for every new application by turning off the router. |

| 3. Easy to install on a router table for better results. |

b) Plunge-Base Routers

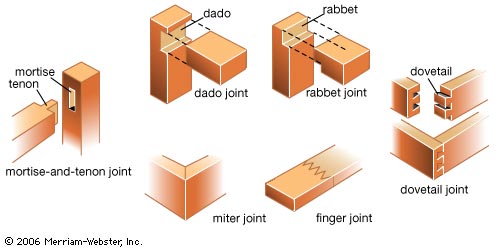

As the name suggests, the plunge-base routers plunge the device a bit downwards in a vertical motion into the workpiece since the housing is supported by two spring-loaded metal posts on the base. You can also control the cutting depth without turning off the routers. They work like a drill press and help you make grooves, mortises, dadoes, rabbets, and with other delicate woodwork. Due to this versatile functioning, they are best for professional use.

| Pros | Cons |

|---|---|

| a) Offer better leverage due to handle placement at a bit higher level from the base. | a) Need training for better use due to their heavy weight |

| b) Versatile and offer delicacy in woodworking. | b) Cannot perform on the fixed-base table |

| c) Give cutting depth of your choice anytime. | |

| d) Provide cuts not only on the edges but also in the middle of the workpiece |

Types of Routers by Size and Power

Keep 3 things in mind when choosing a router:

- The material you would use it on

- The number of times and

- The duration you would use it for

Routers are categorized as HLM on the basis of their size and the power. There are three types of routers under such category.

1. Heavy-Duty Routers

They are the largest in size with motors powerful enough to handle all kinds of router-bits, ranging from smallest round-over bits to the largest panel-raising bits with ease due to the collet’s maximum capacity. Although usually preferred by the pros, you may find it hard to steer them over delicate workpieces by hand due to their heavy weight, size, and power.

2. Light-Duty Routers

Trim routers are light-duty routers, popular among the beginners due to their small size and light weight. You can hold them in one hand to work on the edges using the router-bit under 38 mm in diameter. They are suitable for occasional use with a limited work session, such as for shaping the rough edges, cutting small dadoes, or for small profiling cuts.

3. Medium-Duty Routers

These routers come in between the heavy-and light-duty routers in terms of their structure and function. Therefore, the specifications of both routers make them a better choice for all types of woodworkers.

They also offer a special safety feature; i.e., soft-start that allows the devices to build up their speed slowly without giving several jerks – ideal for newbies as well as pros. They are suitable for dovetailing or mortising. But they cannot tackle heavier requirements due to their average collet size.

Types of Routers by Specifications

1. Computer Numerical Controlled (CNC) Routers

CNC routers are needed when there is a high-demanding project that cannot be handled manually. As the name suggests, they are programmed through computer software and used at the large production units, such as industries, factories or warehouses.

These routers are specially designed to get accurate results. Once the command of the variables like feed rate and cutting depth is given to the computer program, you can produce several copies of a workpiece with both accuracy and precision e.g. when used in the manufacturing of staircases.

2. Combo Router Kits

They are also termed as interchangeable bases. If you want to get a multi-based router, there are kits available with both a plunge and fixed base in them. There is one motor that can fit in both bases, helping you get the benefit of both routers in terms of their applications without paying for two separate tools.

They are the best for users that have to deal with both bases in woodworking. Moreover, these kits are very easy to carry as compared to carrying multiple routers since the only effort is to replace the base. We recommend DEWALT DWP611PK for providing applications such as easy-to-change bases along with an LED light that ensures sufficient visibility for the depth precision.

Conclusion

Whether you are a newbie or a pro in woodworking, we believe now you know what type to go for. Don’t forget to share your experience with us in the comments section below.

FAQs

1. Which direction should you use a wood router?

Ans. You should use it counterclockwise from left to right against the rotation of the router bit.

2. Which is the best router for the beginners?

Ans. The fixed-base router is the best choice for beginners because it is lightweight and has simple functionality.